ZeroHedge - On a long enough timeline, the survival rate for everyone drops to zero

www.zerohedge.com

Tanker, Bulker, LNG Rates Plunge, Container Rates Hold Near Top

FRIDAY, JAN 21, 2022 - 11:00 AM

By Greg Miller of FreightWaves

It’s a tale of two shipping markets. Spot rates remain near historic highs for container shipping; the boom shows no sign of ending. But over in commodity shipping — dry bulk, crude and product tankers, liquefied natural gas (LNG) carriers — spot rates have now sunk below five-year averages.

Crude tankers

Crude tankers

“A bleak outcome,” said brokerage BRS of the recent rates for very large crude carriers (VLCCs; tankers that carry 2 million barrels). “A terrible start of the year,” it said of rates for Suezmaxes (tankers that carry 1 million barrels).

According to Clarksons Platou Securities, average global spot rates for 10-year-old VLCCs fell to just $800 per day on Wednesday. That’s down 90% month on month and down 70% on average year to date versus the same period in 2021, to just a sliver of the breakeven rate of $26,000 per day. (The assessment for the Middle East-China route has just fallen back below zero, to -$400 per day,

implying that freight is not covering the cost of fuel.)

“The end of the holiday season didn’t help push [VLCC] rates up,” said brokerage Banchero Costa.

Clarksons put 10-year-old Suezmax rates at $4,200 per day, down 69% month on month, versus a breakeven of $19,000 per day.

Crude tanker owners

have been bleeding cash for over a year, and the market will have to absorb more new tonnage in 2022 than in 2021. There are 44 VLCCs and 39 Suezmaxes scheduled for delivery this year, versus 35 VLCCs and 23 Suezmaxes in 2021, according to Clarksons.

Product tankers

Crude tanker rates were so bad last year that a record number of newbuild VLCCs carried clean product cargoes during initial voyages after leaving Asian yards,

cannibalizing volumes normally carried by larger product tankers. That practice looks set to continue. “Unfortunately, market information suggests that [VLCC] owners are still eyeing lifting clean cargoes on their newbuilds [into] early Q2 2022,” reported BRS.

As with crude tankers, it’s been a terrible start out the gate for product tankers in 2022.

Clarksons put spot rates for 10-year-old LR2s (larger product carriers with capacity of 80,000-119,999 deadweight tons or DWT) at $5,200 per day on Wednesday, 71% lower month on month and 38% lower on average year to date versus the same period in 2021, to less than a third of their $18,000-per-day breakeven rate.

Rates for smaller 10-year-old MRs (25,000-54,999 DWT) averaged $7,900 per day, down 49% month on month and 22% below their $11,000 breakeven rate.

“The second week of the year followed the same pattern as the first. All of the clean [product] routes are having difficulties,” said Banchero Costa.

Dry bulk

According to Stifel analyst Ben Nolan, “Dry bulk rates have been in freefall in recent weeks, primarily led by the large Capesize [180,000 DWT] vessels, but the weakness has been felt across the board.”

Clarksons estimated Wednesday’s Capesize spot rate at just $10,200 per day, down 55% month on month and far below

the recent peak of $87,000 per day in early September (breakeven for a 10-year-old Capesize is estimated by Clarksons at $17,000 per day). Capesize rates year to date are 20% below their average during the same period last year.

It has been a “brutal start of the year” for Capesizes, said Fearnleys Research.

Spot rates for Panamaxes (bulkers with capacity of 65,000-90,000 DWT) averaged $20,000 per day on Wednesday, 9% lower month on month, while rates for Supramaxes (45,000-60,000 DWT) averaged $20,200 per day, 26% lower month on month.

Month-on-month declines are to be expected now, given dry bulk seasonality, and on a positive note, rates in both of these segments are still sharply higher year to date on average versus the same period in 2021: Panamaxes by 73%, Supramaxes by 94%.

LNG shipping

Spot LNG shipping rates have fallen more steeply in terms of dollars per day than any other bulk commodity shipping segment.

Spot rates of tri-fuel diesel engine (TFDE) LNG carriers shot up to an average of $205,000 per day in late November and early December, according to Clarksons. There were reports of deals as high as $424,000 per day at the peak.

As of Wednesday, Clarksons estimated that TFDE carrier spot rates averaged just $22,000 per day, down 61% week on week and 81% month on month, to around one-ninth of the early December high. The average rate year to date is 76% lower than the same period in 2021.

Unlike dry bulk and tanker markets, however, LNG shipping is primarily a term-charter as opposed to a spot-voyage market, so spot rates are less telling. According to Clarksons Platou Securities analyst Frode Mørkedal, “The spot activity has been remarkably low, with only one voyage charter being done in the first two weeks of 2022. On the other hand, activity in the multi-month market has been healthy.

“The spot market may be under pressure at the moment, but charters continue to seek longer-term charter cover given the market backdrop,” he said.

Container shipping

Rates for crude tankers, product tankers, dry bulk carriers and LNG carriers have all gone the same way in the first few weeks of 2022: down.

Not so for container shipping.

Tanker rates are being weighed by

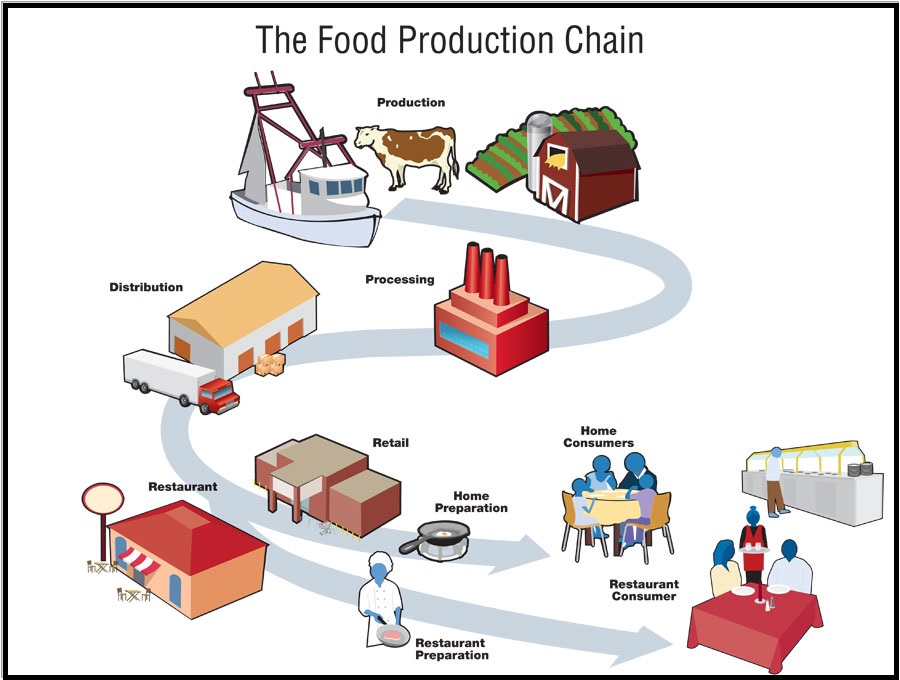

COVID effects on mobility and aviation, and artificially constrained production by OPEC+ members. Dry bulk is being swayed by the Chinese economy (which is faltering) and state policies; seasonal weather conditions in Brazil, Australia and Asia that reduce rates at this time of year; and a coal export ban in Indonesia. LNG shipping rates are being driven by winter weather conditions, the spread in LNG commodity pricing between Europe and Asia, and the shift away from spot deals to long-term charters.

Container shipping rates are being heavily driven by persistently high U.S. consumer demand, which has overwhelmed transport supply,

creating an extreme congestion situation that appears much “stickier” for rates than current drivers in other shipping segments.

The weekly Shanghai Containerized Freight Index is now just short of its all-time high. The weekly Drewry World Container Index (WCI) is at $9,545 per forty-foot equivalent unit, up 12% from early December and up 82% year on year. The WCI is 3.3 times higher year to date than the five-year average for that period.

There were a record high 106 container ships waiting to berth in Los Angeles/Long Beach on Friday, with 99 on Tuesday. On Friday, Maersk pre-announced Q4 2021 results that yet again topped its forecasts: earnings before interest, taxes, depreciation and amortization of $8 billion, bringing its full-year EBITDA to a record-trouncing $24 billion.

On Tuesday, a day when the broader stock market was deep in the red, shares of liner operator Zim hit a new 52-week high, while shares of container-ship lessor Danaos jumped 8% on news of $870 million in fresh charter revenues.

Deutsche Bank analyst Amit Mehrotra pointed to persistent container-shipping rate tailwinds in a research note on Tuesday. He noted that the retail sales-to-inventory ratio is now three standard deviations below its 10-year historical average and that this ratio is inversely correlated with container rates, “which makes sense as lower ratios imply strong consumer demand and the need for inventory restocking.”

“If we assume a reversion to pre-pandemic sales-to-inventory and use current demand, retailers would need $821 billion in inventory. Taking the fastest inventory has grown — which was November 2021, up $12 billion — it would take retailers 17 months to restock.

“While we acknowledge restocking could be faster … as supply chains work themselves out, the resurgence of COVID, in our view, tempers the notion that the unwinding of the supply chain congestion will be … easy.

“We note that the

LA/LB ports have three times the number of ships waiting as they did at the same point last year. In our view, it appears likely that the need for inventory restocking will be a persistent issue in 2022, with the likelihood of continuing into 2023.”