ZeroHedge - On a long enough timeline, the survival rate for everyone drops to zero

www.zerohedge.com

Seniors To The Rescue? New Truckers Over-50 Could Solve Driver Shortage

FRIDAY, NOV 19, 2021 - 05:40 PM

By Noi Mahoney of FreightWaves,

Laura Reny has been an over-the-road truck driver since 2014. The Idaho resident got into the trucking industry full time to pay the bills after her husband passed away from a long illness. She was 63 when she first took the wheel with her CDL as a widow.

She’s now 70 — and has no plans to stop anytime soon.

“I enjoy truck driving, I tell a lot of people that it’s a good job for women and old people, and I’m both,” Reny said.

Ed Falls, 57, retired from a 30-year career as a school band director before he became a truck driver full time about two years ago. Falls wanted a change from teaching and driving a truck seemed like something he could do for a living.

“It was just time for me to do something else and I always like driving,” Falls said. “I like over-the-road stuff. I like the freedom.”

While the U.S. trucking industry continues to face a shortage of qualified drivers, a sometimes overlooked aspect of the market could be recruiting older drivers.

The median age of over-the-road drivers is 46 and the average age of a new truck driver being trained is 35, according to a 2019 report from the American Trucking Associations.

The ATA study estimates that the industry could be short by as many as 160,000 drivers by 2028. The trucking industry currently has about

2 million drivers, according to the U.S. Bureau of Labor Statistics.

For some people, a truck driving career is all about timing. John Albert said becoming a truck driver was easier as an empty nester.

“If I was younger and I still had children at home, I would not do it,” said Albert, who is now 69 and started truck driving when he was 55.

Travis Bacon, manager of driver recruiting at

Prime Inc., doesn’t usually see recruits in their 60s or 70s in the company’s CDL training program.

Prime is a Springfield, Missouri-based refrigerated, flatbed, tanker and logistics trucking company with more than 8,000 drivers. Like most carriers in the industry, Prime is always on the lookout for truck drivers. Each week, up to 120 new student drivers begin orientation at Prime aiming to get their Class A CDLs. Of those new students, usually a handful are 50 or older.

“I do see plenty of 50-year-olds starting. For the most part, it’s guys in their early 20s that are getting started, just what you would expect,” Bacon said. “We do occasionally see 50-year-olds, sometimes older, maybe a guy or two every week.”

Most applicants arriving at orientation already know some information about the trucking industry, Bacon said.

“We’re kind of painting the picture for them. You’re sleeping in the box in the truck. You’re showering at truck stops, you’re away from home for a few weeks at a time, you’re traveling all over the country and you’ve got to be ready for any type of weather,” Bacon said. “There’s also some perks to [truck driving]. There’s not a boss breathing down your neck 99% of the time, you’re kind of just cruising down the highway, listening to music or whatever you like, but driving takes a lot of focus.”

Reny has had two stints working as a truck driver over the last 30 years. The first was from 1988 to 1993, after she got out of the Air Force, and her second career as a driver began under sad circumstances.

“My husband had suffered a traumatic brain injury in 1996. For the next 18 years I took care of him. He went downhill in 2014,” Reny said. “I knew I wasn’t able to care for him any longer. I went ahead and put him in a nursing home. In the meantime, I had gotten my CDL because when I drove before I had a chauffeur’s license and wasn’t able to transfer it over to CDL.”

Reny works as a long-haul truck driver for GLS Carriers, driving as much as 13,500 miles a month. She has hauled loads through all lower 48 states and in every weather condition. Reny describes driving down on the road as a “busy” experience.

“My head is always on a swivel to watch traffic around me, because you have to watch all the other vehicles around you, most people drive very unconsciously,” Reny said.

One of the best parts about truck driving for Reny is the money.

“The money for sure,” said Reny, who makes roughly $75,000 a year. “Because I had no savings and Social Security is only like $1,500 a month, with my house payment and other stuff, that would be tough to live on.”

Albert also said the money has been good driving a truck. He’s made more money in the last 14 years as a trucker than he did the previous 30 years working in other industries.

“The very first year I started driving I made $55,000, and I’ve probably made a million dollars gross pay in 14 years driving a truck,” Albert said.

Albert started working as a truck driver after working in a ministry.

“The very hardest part for me, like most people, was backing,” Albert said. “It took about six months to a year, then all of a sudden the light bulb came on and it became a lot easier. I kept trying to turn the trailer into a spot, but you don’t actually turn it. You push it. When I cranked the wheels one way, it was going to push that trailer the other way. That became a little easier for me.”

Falls said he completed his CDL training at a local community college in Michigan but really learned how to drive a truck on the job.

“The CDL training was very good at preparing me for the test, getting my CDL,” Falls said. “As far as day-to-day driving on the road, bigger stuff, not too helpful there.”

Falls said the first time he was out on his own he was driving a truck on Interstate 80 through the Chicago area to Gary, Indiana.

“I was pretty confident behind the wheel, but I was also aware that I had a lot to learn so I tried to be very aware of what was going on around me. For example, when I was in areas where the traffic was heavier,” Falls said. “I would make sure that the radio was off so that I could really focus on what I was doing, no distractions.”

Falls currently works Monday through Friday and is home on weekends. He said managing time and concentrating on the road are his most important tips for drivers of any age.

“You need to be aware of the things that distract you personally, develop strategies to account for them,” Falls said.

Albert currently works as a driver for

Nussbaum Transportation, for which he makes runs during the week, but like Falls is home mostly every weekend now.

“I used to do over-the-road trucking, be gone sometimes five weeks at a time, I can’t do that anymore,” Albert said.

About 18 months ago, Alberts contracted COVID-19, which kept him in a hospital for two weeks.

“I was like an inch away from having to go on a ventilator,” Albert said. “I feel privileged to still be doing what I’m doing.”

Albert said one of his favorite parts about the job is seeing the country and least favorite is delays.

“I’ve always enjoyed seeing the sights. I’ve seen deer, bears, elk and moose. I’ve even seen a wolf,” Albert said. “Unfortunately I’ve seen a lot of bad accidents too. The frustrating parts are accidents, construction, delays and stuff.

Albert said one of the biggest differences he sees between older drivers and younger ones are missed delivery appointments.

“One of the big things that helped me in trucking is that my biggest pet peeve in life is tardiness,” Albert said. “You have got to be on time when you’re driving a truck.”

Albert’s advice for anyone thinking of becoming a truck driver is to “count the costs.”

“That’s how much money you make versus the sacrifice you’re going to have to make, because they’re large,” Albert said. “I think too many people get into trucking and think it’s a glamorous thing, but it is anything but glamorous. So counting the costs I think is No. 1.”

Falls said anyone thinking of becoming a truck driver should be self motivated and open to learning new things.

“Talk to people and be open to suggestions,” Falls said.

Reny’s advice for new truck drivers is to learn how to save money.

“If you’re doing it because you need a certain level of money, you need to be prepared for that ahead of time, because it’s going to take an astute person to make more than $45,000 their first year,” Reny said.

Reny hopes to keep driving for another two years so she can pay off her house and buy a new pickup truck and camper to travel around the U.S.

“I’ll go visit friends and family and make a nuisance of myself. I want to really see the country,” Reny said.

www.zerohedge.com

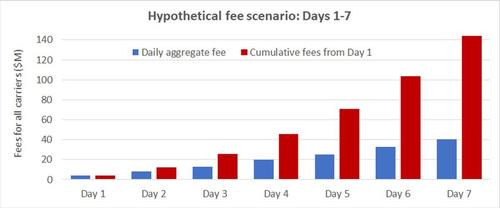

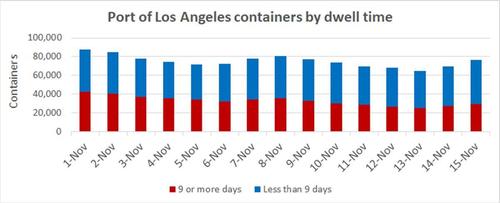

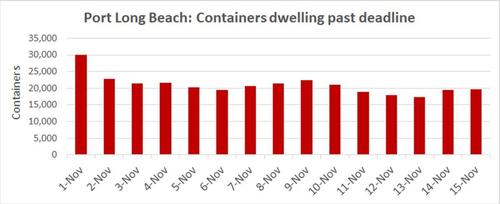

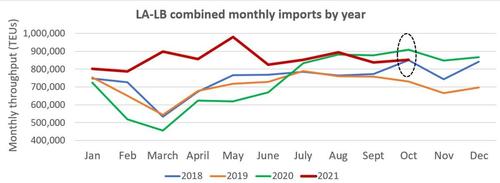

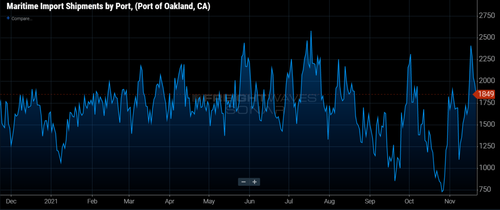

Chart: American Shipper. Scenario assumes Nov. 1-10 rate of excess-dwell-container decline continues and average late container durations. Does not include Los Angeles intermodal late fees.

Chart: American Shipper. Scenario assumes Nov. 1-10 rate of excess-dwell-container decline continues and average late container durations. Does not include Los Angeles intermodal late fees.

Recently, truckers were lined up for nearly two miles outside of the Port of Oakland. Image: Bill Aboudi/AB Trucking.

Recently, truckers were lined up for nearly two miles outside of the Port of Oakland. Image: Bill Aboudi/AB Trucking.

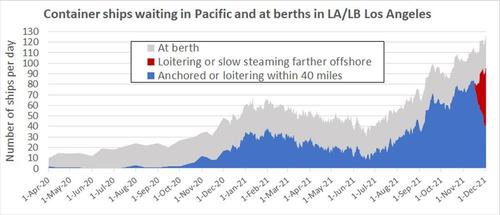

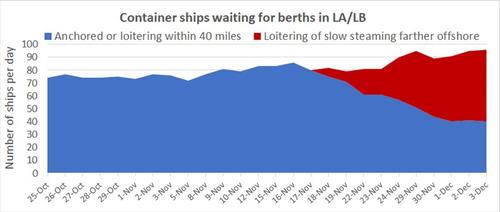

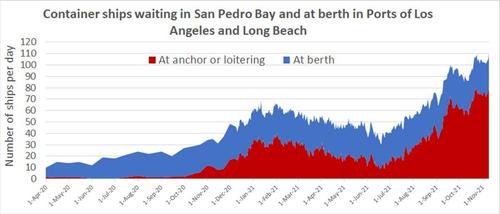

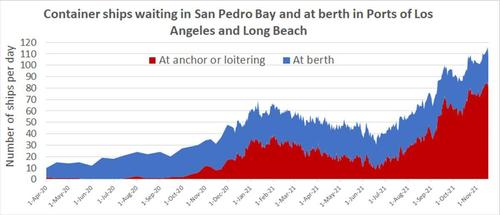

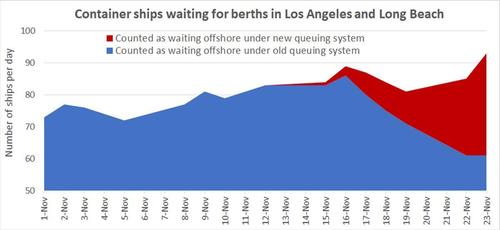

Chart: American Shipper based on data from the Marine Exchange of Southern California. Counted under old system: ships reported by the Marine Exchange comprising number at anchor plus loitering within 40 miles. Counted under new system: ships with Calculated Time of Arrival prior to that day’s Master Queuing List time.

Chart: American Shipper based on data from the Marine Exchange of Southern California. Counted under old system: ships reported by the Marine Exchange comprising number at anchor plus loitering within 40 miles. Counted under new system: ships with Calculated Time of Arrival prior to that day’s Master Queuing List time.

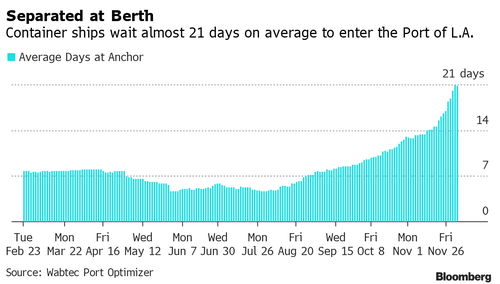

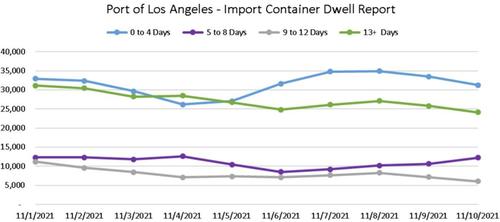

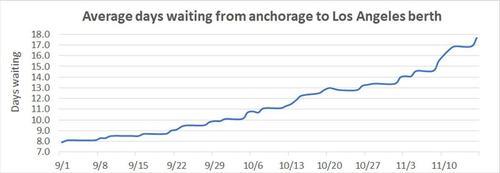

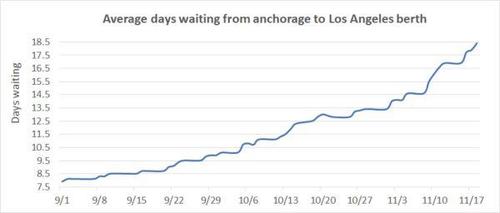

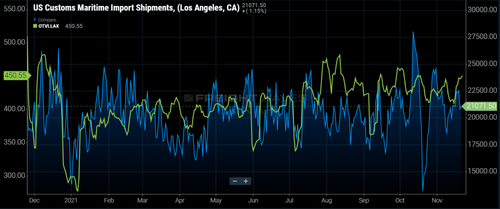

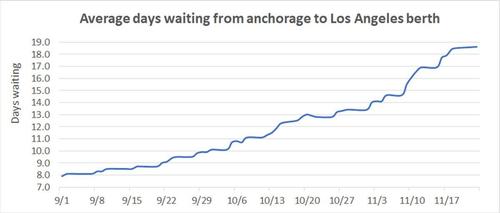

Chart: American Shipper based on data from the Port of Los Angeles, Port Optimizer: Note: Average is 30-day moving average

Chart: American Shipper based on data from the Port of Los Angeles, Port Optimizer: Note: Average is 30-day moving average