marsh

On TB every waking moment

[COMMENT: Article on website is rich with media accents]

Inside America’s Broken Supply Chain

How industry failures to collaborate and

share information left the system vulnerable

By

David J. Lynch

Updated Oct. 2 at 7:00 p.m.Originally published Sept. 30, 2021

REPORTING FROM LOS ANGELES AND JOLIET, ILL.

The commercial pipeline that each year brings $1 trillion worth of toys, clothing, electronics and furniture from Asia to the United States is clogged and no one knows how to unclog it.

This month, the median cost of shipping a standard rectangular metal container from China to the West Coast of the United States hit a record $20,586, almost twice what it cost in July, which was twice what it cost in January, according to the Freightos index. Essential freight-handling equipment too often is not where it’s needed, and when it is, there aren’t enough truckers or warehouse workers to operate it.

As Americans fume, supply headaches that were viewed as temporary when the coronavirus pandemic began now are expected to last through 2022.

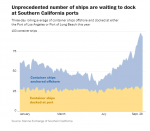

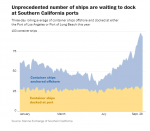

Dozens of cargo vessels stuck at anchor off the California coast illustrate the delivery disruptions that have become the signature feature of the recovery, fueling inflation, sapping growth and calling into question the global economic model that has prevailed for three decades.

Today’s twisted supply chain is forcing companies to place precautionary orders to avoid running out of goods, which only compounds the pressure. Consumers are confronting higher prices and shortages of cars, children’s shoes and exercise gear, as the holiday shopping season looms.

“It’s going to get worse again before it gets better,” said Brian Bourke, chief growth officer at SEKO Logistics. “Global supply chains are not built for this.

Everything is breaking down.”

Fallout from the once-in-a-century health crisis is the chief culprit behind soaring freight bills and delivery delays. Americans trapped at home slashed spending at restaurants, movie theaters and sporting events and splurged on goods such as laptops and bicycles, triggering an import avalanche that has overwhelmed freight channels.

But the pandemic also exposed weaknesses in the nation’s transport plumbing: investment shortfalls at key ports, controversial railroad industry labor cuts, and a chronic failure by key players to collaborate, according to interviews with more than 50 individuals representing every link in the nation’s supply chain.

“It’s like an orchestra with lots of first violins and no conductor. … No one’s really in charge,” said Fran Inman, a Los Angeles-based commercial real estate executive who has advised government agencies on supply issues.

Port of Los Angeles

On Sept. 1, 40 container ships belonging to companies such as Hyundai, NYK Line and Evergreen were anchored off California, waiting for a berth. (Less than three weeks later, the number reached 73.) Some vessels sit for two weeks or more, effectively cutting capacity on trans-Pacific shipping lanes and driving up costs.

“From an economic point of view, it’s a disaster because cargo is waiting,” said Markus Grote, captain of a Hapag-Lloyd container ship.

For goods to move seamlessly from overseas factories to American addresses, the oceangoing vessels, shipping containers, cargo terminals, truckers, chassis providers and railroads all must work together, like runners in a relay race. If equipment gets stuck at any point, delays ripple along the entire chain.

Yet the United States is “decades behind” foreign ports in getting carriers, terminals and shippers to provide each other access to commercial data for planning purposes, said Gene Seroka, executive director of the Port of Los Angeles. Concerns over data privacy, business secrets and security have resulted in a fragmented approach. Individual ports operate as separate fiefdoms rather than as part of a national system.

In the Dutch city of Rotterdam, Europe’s largest port, everyone involved in a cargo vessel’s arrival sees the same information on a common data-sharing platform. Called “PortXchange,” the software makes port calls “smarter and more efficient” than the use of separate systems or the telephone, according to the port’s website.

Seroka touts a tool called the Port Optimizer, which forecasts three weeks of incoming cargo. More information sharing — including over a longer time period — would allow carriers, terminals, truckers and dockworkers to better position equipment and people. But other than Los Angeles, New Orleans is the only U.S. port that is even testing the system.

“Information sharing and additional transparency is one of the few areas where indisputably we could get more capacity out of the current system,” said Dan Maffei, chairman of the Federal Maritime Commission.

To be sure, the United States is importing historic amounts of goods. The L.A. port expects this year to handle a record 10.8 million containers. To keep pace, the International Longshore and Warehouse Union has accelerated training of new workers. Twenty union members have died of covid-19 while working through the pandemic, the union said.

“Our members are tired. Our members are feeling the pain of these covid deaths,” said Mike Podue, president of ILWU Local 63. “We’re lucky there hasn’t been a major accident.”

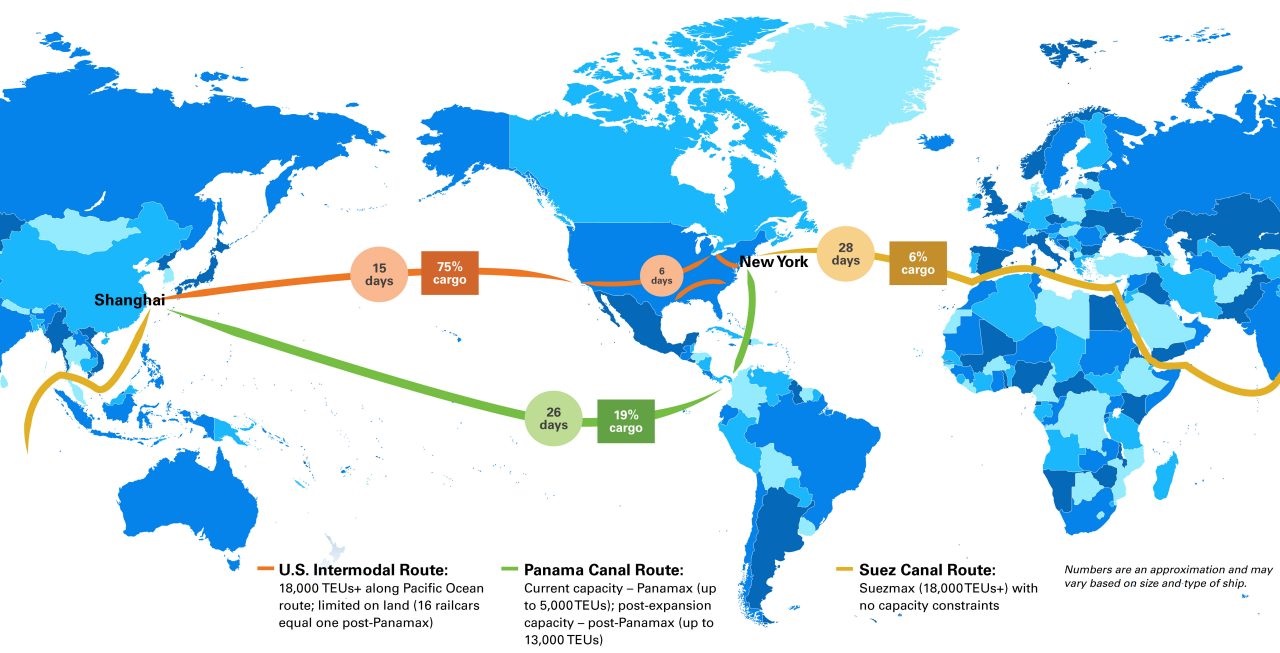

When the supply chain works, goods flow continuously, as if borne along by a river. Today, one bottleneck follows another. The problems are especially acute on the Asia-to-U.S. trade route.

Once a berth becomes available, longshoremen operating massive blue cranes lift the metal containers and position them to head inland via truck or train.

Ideally, a truck driver who has been alerted to the presence of a customer’s goods arrives at a terminal to find a chassis waiting. The container is then hoisted aboard and the driver pulls the chassis to the customer’s warehouse.

But too often, congestion elsewhere keeps the port jammed. Shippers with full warehouses won’t dispatch drivers to collect additional containers. Many loaded chassis sit outside overstuffed warehouses for days waiting to be unloaded, leaving ports short of needed equipment.

Why containers are stacked up at the ports of L.A. and Long Beach

Dan Walsh from TRAC Intermodal shows how a chassis is critical to keeping everything moving. (Lee Powell/TWP) https://d21rhj7n383afu.cloudfront.n...3924746e0fb000782999a/file_640x360-600-v3.mp4 1:27 min

Even as cargo piles up on the docks, almost a third of the port’s night-shift appointments for truckers go unfilled.

At APM Terminals, the largest container site in the Western Hemisphere, the air echoes with truck horns, air brakes and the warning beeps of mobile cranes.

This 484-acre facility boasts 12 miles of railroad tracks, linking the docks to points east for customers such as Walmart, Nike and Ikea. Across from the headquarters building, trucks wait to navigate canyons of containers stacked about 50 feet high.

Steven Trombley, the facility’s managing director, needs the agility of a hockey goalie to ward off the daily complications. Today, his berths are full and four of the ships loitering in San Pedro Bay are impatient for a spot.

Trombley has nearly a week’s worth of truck chassis on the dock. But truckers are scarce. Such mismatches help explain why containers destined to travel by rail sit dockside for an average of eight days, up from two before the pandemic.

“It’s a headache. Cargo is sitting here longer than planned,” Trombley said. “If I don’t get the cargo moving, then the next ship is not going to have space.”

Even as total federal ports spending has increased, the L.A. gateway has been neglected, Seroka said. West Coast ports, including the L.A.-Long Beach complex, which handles about 36 percent of U.S. imports, have lagged East and Gulf Coast facilities over the past decade, $11 billion to $1 billion.

With more money, the port could have expanded channels, fortified wharves and improved road and rail links, he said.

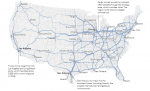

One shortcoming: The lack of a direct rail connection to the distribution centers for companies such as Amazon and Nordstrom 75 miles east in California’s “Inland Empire.” (Amazon founder Jeff Bezos owns The Washington Post.)

Advocates of a rail link say it would eliminate from Southern California’s freeways thousands of daily truck trips and ease port congestion by moving millions of containers off the docks. But the railroads doubt the financial case.

The backlog got so bad last fall that port officials opened overflow lots to store thousands of containers.

At Pier S, on the other end of a harbor island from APM, about 7,300 containers and chassis are parked. Some have been sitting for almost three weeks.

One of the facility’s users is TRAC Intermodal, the nation’s largest chassis operator. CEO Dan Walsh, a wisecracking Australian, said current supply snags reflect Americans’ greater reliance upon e-commerce.

“They expect things to come faster, which puts pressure on everyone in the supply chain,” he said. “They also expect to be able to return things without cost.”

TRAC has spent $1 billion over the past decade upgrading its 180,000-vehicle fleet for what Walsh calls “the permanent whitewater of daily work.”

The company has increased spending by 20 percent this year, adding models that boast GPS locaters, LED lights and anti-lock brakes. But expanding more aggressively to meet the cargo emergency would not be cost effective: new tariffs have made Chinese models unaffordable at a time when domestic makers struggle to fill orders.

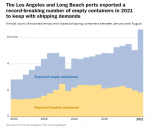

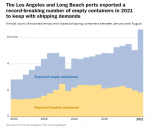

As demand for shipping has soared, carriers have grown choosy about what they carry — eschewing hazardous chemicals and heavier products that increase vessel fuel costs. They often decline to send containers inland to collect American farm exports, preferring to rush them back to Asia to capitalize on high eastbound freight rates.

That’s why the L.A. port exports three times as many empty containers as full ones.

Part 1 of 2

Inside America’s Broken Supply Chain

How industry failures to collaborate and

share information left the system vulnerable

By

David J. Lynch

Updated Oct. 2 at 7:00 p.m.Originally published Sept. 30, 2021

REPORTING FROM LOS ANGELES AND JOLIET, ILL.

The commercial pipeline that each year brings $1 trillion worth of toys, clothing, electronics and furniture from Asia to the United States is clogged and no one knows how to unclog it.

This month, the median cost of shipping a standard rectangular metal container from China to the West Coast of the United States hit a record $20,586, almost twice what it cost in July, which was twice what it cost in January, according to the Freightos index. Essential freight-handling equipment too often is not where it’s needed, and when it is, there aren’t enough truckers or warehouse workers to operate it.

As Americans fume, supply headaches that were viewed as temporary when the coronavirus pandemic began now are expected to last through 2022.

Dozens of cargo vessels stuck at anchor off the California coast illustrate the delivery disruptions that have become the signature feature of the recovery, fueling inflation, sapping growth and calling into question the global economic model that has prevailed for three decades.

Today’s twisted supply chain is forcing companies to place precautionary orders to avoid running out of goods, which only compounds the pressure. Consumers are confronting higher prices and shortages of cars, children’s shoes and exercise gear, as the holiday shopping season looms.

“It’s going to get worse again before it gets better,” said Brian Bourke, chief growth officer at SEKO Logistics. “Global supply chains are not built for this.

Everything is breaking down.”

Fallout from the once-in-a-century health crisis is the chief culprit behind soaring freight bills and delivery delays. Americans trapped at home slashed spending at restaurants, movie theaters and sporting events and splurged on goods such as laptops and bicycles, triggering an import avalanche that has overwhelmed freight channels.

But the pandemic also exposed weaknesses in the nation’s transport plumbing: investment shortfalls at key ports, controversial railroad industry labor cuts, and a chronic failure by key players to collaborate, according to interviews with more than 50 individuals representing every link in the nation’s supply chain.

“It’s like an orchestra with lots of first violins and no conductor. … No one’s really in charge,” said Fran Inman, a Los Angeles-based commercial real estate executive who has advised government agencies on supply issues.

Port of Los Angeles

On Sept. 1, 40 container ships belonging to companies such as Hyundai, NYK Line and Evergreen were anchored off California, waiting for a berth. (Less than three weeks later, the number reached 73.) Some vessels sit for two weeks or more, effectively cutting capacity on trans-Pacific shipping lanes and driving up costs.

“From an economic point of view, it’s a disaster because cargo is waiting,” said Markus Grote, captain of a Hapag-Lloyd container ship.

For goods to move seamlessly from overseas factories to American addresses, the oceangoing vessels, shipping containers, cargo terminals, truckers, chassis providers and railroads all must work together, like runners in a relay race. If equipment gets stuck at any point, delays ripple along the entire chain.

Yet the United States is “decades behind” foreign ports in getting carriers, terminals and shippers to provide each other access to commercial data for planning purposes, said Gene Seroka, executive director of the Port of Los Angeles. Concerns over data privacy, business secrets and security have resulted in a fragmented approach. Individual ports operate as separate fiefdoms rather than as part of a national system.

In the Dutch city of Rotterdam, Europe’s largest port, everyone involved in a cargo vessel’s arrival sees the same information on a common data-sharing platform. Called “PortXchange,” the software makes port calls “smarter and more efficient” than the use of separate systems or the telephone, according to the port’s website.

Seroka touts a tool called the Port Optimizer, which forecasts three weeks of incoming cargo. More information sharing — including over a longer time period — would allow carriers, terminals, truckers and dockworkers to better position equipment and people. But other than Los Angeles, New Orleans is the only U.S. port that is even testing the system.

“Information sharing and additional transparency is one of the few areas where indisputably we could get more capacity out of the current system,” said Dan Maffei, chairman of the Federal Maritime Commission.

To be sure, the United States is importing historic amounts of goods. The L.A. port expects this year to handle a record 10.8 million containers. To keep pace, the International Longshore and Warehouse Union has accelerated training of new workers. Twenty union members have died of covid-19 while working through the pandemic, the union said.

“Our members are tired. Our members are feeling the pain of these covid deaths,” said Mike Podue, president of ILWU Local 63. “We’re lucky there hasn’t been a major accident.”

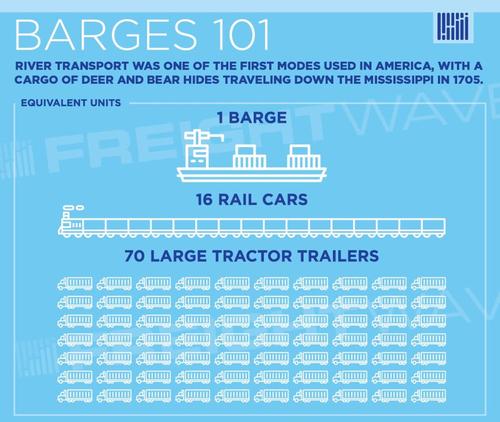

When the supply chain works, goods flow continuously, as if borne along by a river. Today, one bottleneck follows another. The problems are especially acute on the Asia-to-U.S. trade route.

Once a berth becomes available, longshoremen operating massive blue cranes lift the metal containers and position them to head inland via truck or train.

Ideally, a truck driver who has been alerted to the presence of a customer’s goods arrives at a terminal to find a chassis waiting. The container is then hoisted aboard and the driver pulls the chassis to the customer’s warehouse.

But too often, congestion elsewhere keeps the port jammed. Shippers with full warehouses won’t dispatch drivers to collect additional containers. Many loaded chassis sit outside overstuffed warehouses for days waiting to be unloaded, leaving ports short of needed equipment.

Why containers are stacked up at the ports of L.A. and Long Beach

Dan Walsh from TRAC Intermodal shows how a chassis is critical to keeping everything moving. (Lee Powell/TWP) https://d21rhj7n383afu.cloudfront.n...3924746e0fb000782999a/file_640x360-600-v3.mp4 1:27 min

Even as cargo piles up on the docks, almost a third of the port’s night-shift appointments for truckers go unfilled.

At APM Terminals, the largest container site in the Western Hemisphere, the air echoes with truck horns, air brakes and the warning beeps of mobile cranes.

This 484-acre facility boasts 12 miles of railroad tracks, linking the docks to points east for customers such as Walmart, Nike and Ikea. Across from the headquarters building, trucks wait to navigate canyons of containers stacked about 50 feet high.

Steven Trombley, the facility’s managing director, needs the agility of a hockey goalie to ward off the daily complications. Today, his berths are full and four of the ships loitering in San Pedro Bay are impatient for a spot.

Trombley has nearly a week’s worth of truck chassis on the dock. But truckers are scarce. Such mismatches help explain why containers destined to travel by rail sit dockside for an average of eight days, up from two before the pandemic.

“It’s a headache. Cargo is sitting here longer than planned,” Trombley said. “If I don’t get the cargo moving, then the next ship is not going to have space.”

Even as total federal ports spending has increased, the L.A. gateway has been neglected, Seroka said. West Coast ports, including the L.A.-Long Beach complex, which handles about 36 percent of U.S. imports, have lagged East and Gulf Coast facilities over the past decade, $11 billion to $1 billion.

With more money, the port could have expanded channels, fortified wharves and improved road and rail links, he said.

One shortcoming: The lack of a direct rail connection to the distribution centers for companies such as Amazon and Nordstrom 75 miles east in California’s “Inland Empire.” (Amazon founder Jeff Bezos owns The Washington Post.)

Advocates of a rail link say it would eliminate from Southern California’s freeways thousands of daily truck trips and ease port congestion by moving millions of containers off the docks. But the railroads doubt the financial case.

The backlog got so bad last fall that port officials opened overflow lots to store thousands of containers.

At Pier S, on the other end of a harbor island from APM, about 7,300 containers and chassis are parked. Some have been sitting for almost three weeks.

One of the facility’s users is TRAC Intermodal, the nation’s largest chassis operator. CEO Dan Walsh, a wisecracking Australian, said current supply snags reflect Americans’ greater reliance upon e-commerce.

“They expect things to come faster, which puts pressure on everyone in the supply chain,” he said. “They also expect to be able to return things without cost.”

TRAC has spent $1 billion over the past decade upgrading its 180,000-vehicle fleet for what Walsh calls “the permanent whitewater of daily work.”

The company has increased spending by 20 percent this year, adding models that boast GPS locaters, LED lights and anti-lock brakes. But expanding more aggressively to meet the cargo emergency would not be cost effective: new tariffs have made Chinese models unaffordable at a time when domestic makers struggle to fill orders.

As demand for shipping has soared, carriers have grown choosy about what they carry — eschewing hazardous chemicals and heavier products that increase vessel fuel costs. They often decline to send containers inland to collect American farm exports, preferring to rush them back to Asia to capitalize on high eastbound freight rates.

That’s why the L.A. port exports three times as many empty containers as full ones.

Part 1 of 2

Now he is going to make the LA port start working 24/7. I would have thought that ports already work 24/7.

Now he is going to make the LA port start working 24/7. I would have thought that ports already work 24/7.

Thousands of shipping containers at the Port of Felixstowe in Suffolk, England, on Oct. 13, 2021. (Joe Giddens/PA)

Thousands of shipping containers at the Port of Felixstowe in Suffolk, England, on Oct. 13, 2021. (Joe Giddens/PA)

There are about 25,000 miles of navigable waterways — including rivers, canals and coastal routes — across the United States. Pictured is the Houston Ship Channel, which intersects with the Gulf Intracoastal Waterway.

There are about 25,000 miles of navigable waterways — including rivers, canals and coastal routes — across the United States. Pictured is the Houston Ship Channel, which intersects with the Gulf Intracoastal Waterway.

OOIDA warns drivers could be sidelined due to testing disruptions. (Photo: Jim Allen/FreightWaves)

OOIDA warns drivers could be sidelined due to testing disruptions. (Photo: Jim Allen/FreightWaves)