No. For the love of Heaven Congress should stay the F OUT OF IT!

Pelosi: Congress must 'address' supply chain issues, which have a 'direct impact on everything'

In California, U.S. ports are reportedly operating at 60%-70% capacity.justthenews.com

Pelosi: Congress must 'address' supply chain issues, which have a 'direct impact on everything'

In California, U.S. ports are reportedly operating at 60%-70% capacity.

Updated: October 12, 2021 - 11:07pm

House Speaker Nancy Pelosi says the U.S. government needs to intervene in the supply chain problems hurting the U.S. economy and the lack of manpower at U.S. ports.

In California, U.S. ports are reportedly operating at 60%-70% capacity. In addition, supply chain issues have delayed production of many types of products, including vehicles. Prices are rising, in part, due to the supply chain problems and inflation.

"As the global economic recovery continues to gather steam, what is increasingly apparent is how it will be stymied by supply-chain disruptions that are now showing up at every corner" of the economy, Moody's Analytics warned in a report Monday.

Dealers across the country are adding "market adjustment" fees on top of the retail price of vehicles as a result of the shortage of new cars on their lots.

The "shortages and delays have become a source of concern about fair competition," according to a New York Times report on supply chain problems during the pandemic heading into the holiday season.

Major retailers like Target and Home Depot are chartering their own ships as a way to get around the supply chain issues. The ships costs millions of dollars to lease, which is not a viable option for smaller-sized companies.

Pelosi, a California Democrat, was asked if the federal government is going to address the supply chain problems and the delays moving products at U.S. ports.

"The supply chain is not just an issue about what happens here," Pelosi said at a news conference at the Capitol on Tuesday. "The supply chain is an issue globally, and that was something we talked about at the meeting because there are obstructions in other countries of product, even making it to the ships to come to our country." Pelosi was referring to her meetings with foreign leaders at the G20 Parliamentary Speakers' Summit and the NATO Parliamentary Assembly.

"Yeah, we've got to address that issue because it has a direct impact on everything because we're so dependent on global trade and our trade going out as well," she added.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ECON Inside America’s Broken Supply Chain How industry failures to collaborate and share information left the system vulnerable

- Thread starter marsh

- Start date

marsh

On TB every waking moment

White House Chief Klain criticized for retweet saying inflation, supply chain 'high class issues'

"Ron are u serious?," a person asked on Twitter. "You ever have to live off a loaf bread and a jar of peanut butter ... ."

White House Chief Klain criticized for retweet saying inflation, supply chain 'high class issues'

"Ron are u serious?," a person asked on Twitter. "You ever have to live off a loaf bread and a jar of peanut butter ... ."

Updated: October 15, 2021 - 8:23am

White House Chief of Staff Ron Klain is facing backlash for retweeting a post from a Harvard professor saying the country's pressing inflation and supply chain problems are "high class issues," with critics saying his tweet was tone deaf to working-class Americans struggling with rising prices.

Klain on Wednesday night retweeted the post by professor Jason Furman, who was also chairman of the Council of Economic Advisers in the Obama administration, saying, "Most of the economic problems we're facing (inflation, supply chains, etc.) are high class problems. We wouldn't have had them if the unemployment rate was still 10 percent. We would instead have had a much worse problem.”

In Klain’s retweet, he wrote, "This," along with emoji two hands pointing downward.

"Ron are u serious?,” responded @iamthekz. "This is your defense? You ever have to live off a loaf bread and a jar of peanut butter not because you are hiking the Appalachian Trail? I have at points in last decade depended upon my Speedway reward points to get me gas & a hot dog before payday…"

A second-month-in-a-row increase in the country's Consumer Price Index in September sent inflation up 5.4% from where it was a year ago and matched the largest increase since 2008.

Supply chain issues have also made scarce and increased prices in the U.S. on goods and products – from computer chips for vehicles and washing machines to paper towels and furniture.

White House press secretary Jen Psaki on Thursday attempted to defend Klain's retweet by, she said, putting in into "full context" and said the volume and content of his tweets is not a "top priority" for the administration.

"So I think the point here is, what some of these critics are saying is we don’t know if what they’re saying is if what they thought was great was when the unemployment rate was double what it is today," Psaki said. "Or when people were locked in their homes and therefore gas prices were lower. We’re at this point because the unemployment rate has come down and been cut in half because people are buying more goods because people are traveling and because demand is up."

marsh

On TB every waking moment

Zerohedge

ZeroHedge - On a long enough timeline, the survival rate for everyone drops to zero

#EmptyShelvesJoe Trends On Twitter Amid Supply Chain Snarls

FRIDAY, OCT 15, 2021 - 06:10 PM

The hashtag #EmptyShelvesJoe was one of the hottest trends across Twitter Thursday as people en masse are waking up to the fact that international supply chains are clogged, and shortages have resulted in empty store shelves at their local retailer.

The hashtag, number one in the US on Thursday, comes one day after President Biden issued a port directive to operate 24/7 to alleviate snarled supply chains.

But the move to have Ports of Los Angeles and Long Beach, a point of entry for 40% of all US containerized goods, work in hyperdrive to alleviate congestion is "too little, too late" to save Christmas, said one top toymaker.

Earlier this week, 80 container ships are at anchor and 64 at berths across the twin ports. The backlog doesn't stop there as it takes well more than a week for entry into the port. Once the containers are unloaded, it takes another week to leave the port to warehouses.

Those tweeting the hashtag placed most of the blame on Biden and Transportation Secretary Pete Buttigieg for their inability to normalize supply chains as congestion creates shortages of consumer goods and rapid inflation.

An aerial visual of the backlog at the Port of Los Angeles shows tens of thousands of containers are sitting dockside. Some have said it's the lack of truck drivers that have resulted in delays.

View: https://twitter.com/i/status/1448702084874915843

.37 min

"Are f**king container yards are stuffed," said one Twitter user.

View: https://twitter.com/i/status/1448713859255123976

.34 min

As the hashtag continued to go viral on Thursday afternoon, Twitter police decided to remove it from the list of trending topics.

View: https://twitter.com/i/status/1448861443730771977

.59 min

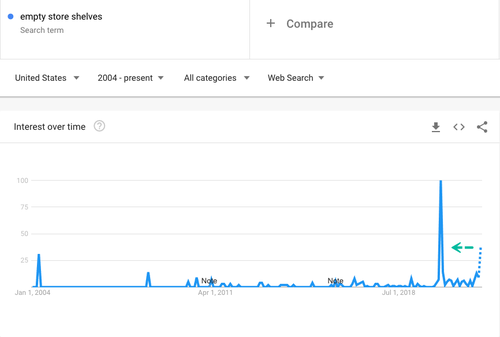

"Empty store shelves" on Google Trends is also surging.

Here are some tweets of people across the county complaining about empty store shelves and using the #EmptyShelvesJoe hashtag.

View: https://twitter.com/i/status/1448791694900703232

.29 min

According to the latest Rasmussen poll, "62% of Americans say they've already noticed shortages of basic items in stores where they live."

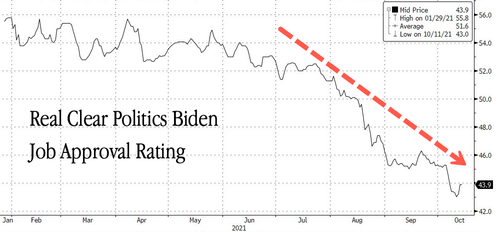

Broken supply chains, raging inflation in energy, food, and housing, and the overall cost of living getting more expensive - compound this all with shortages of consumer goods, the president's job approval number continues to tumble.

One can assume with congested supply chains unlikely to abate anytime soon, Biden will be blamed on Twitter for ruining Christmas as certain consumer goods won't make it under the tree this year.

Finally, just in case you wondered who was to blame for "empty shelves", here is Joe Biden himself explaining it last year... "We don't have a food shortage problem — we have a leadership problem."

View: https://twitter.com/i/status/1263269526721855488

1:38 min

marsh

On TB every waking moment

Zerohedge

ZeroHedge - On a long enough timeline, the survival rate for everyone drops to zero

Ford Halts Production At Mexico Plant Amid Snarled Supply Chains

FRIDAY, OCT 15, 2021 - 01:45 PM

The Ford Motor Company Hermosillo assembly plant in Hermosillo, the capital city of the Mexican state of Sonora, temporarily suspended operations Friday due to a shortage of materials, according to Reuters, citing the plant's labor union.

The Hermosillo assembly plant currently assembles the Bronco Sport SUV and Maverick compact pickups for the North American market. Production of those vehicles was halted Friday due to supply shortages - there was no mention of what supplies were in short stock.

The union said workers would be paid 75% of their salaries on Friday. This isn't the first time the plant has shuttered operations. The last time was between Oct. 11-12.

Ford has struggled all year to maintain consistent operations at its assembly plants due to the impact of the global chip shortage. Lately, the company recently suspended production at its Flat Rock, Michigan, plant and another facility in Kansas City, Missouri.

Last month, Ford CEO Jim Farley told Yahoo Finance that semiconductors shortages continue to challenge the company but see better conditions in the fourth quarter than third. He acknowledged the chip shortage will be an issue for the auto industry into 2022.

Ford's dealer inventories are extremely thin. As of the first of this month, there were 236,000 vehicles in stock with about a 38-day supply, well below the average 60- to 70-day supply. Sales have also plunged, down 27.6% in the third quarter from a year ago and 31.5% from the third quarter of 2019.

Declining sales and limited supply come as average new car prices continue to skyrocket to new highs.

marsh

On TB every waking moment

Zerohedge

ZeroHedge - On a long enough timeline, the survival rate for everyone drops to zero

Empty Christmas Stockings? Don't Blame COVID, Blame California

FRIDAY, OCT 15, 2021 - 11:30 AM

Authored by Andrea Widburg via AmericanThinker.com,

The conventional wisdom from the left is that COVID is the reason that shipping containers are in the waters off California with no stevedores or truckers available to take care of them.

The implication, of course, is that if people would stop being selfish and take the vaccines, the whole problem would magically vanish.

That’s nonsense.

As a couple of astute articles explain, the problem is that California has passed two laws—one for “climate change” and the other as a sop to the unions—that destroyed much of California’s trucking industry.

Add in woes unique to the industry and COVID payments that discourage people from working and...voila!...empty Christmas stockings.

Stephen Green, at PJ Media, explains some of what’s going on.

As a preliminary matter, truckers are aging out of the job and new ones aren’t coming along. Because federal law requires that truckers be at least 21, kids who leave school at 17 or 18 get involved in other careers, leaving trucker shortfalls. Women don’t offset this problem because, as is typical for most physically difficult jobs, it’s not their thing. Those are long-term problems.

The short-term problem, though, is that California has passed laws taking trucks off the road:

Twitter user Jerry Oakley reminds us that “Carriers domiciled in California with trucks older than 2011 model, or using engines manufactured before 2010, will need to meet the Board’s new Truck and Bus Regulation beginning in 2020.” Otherwise, “Their vehicles will be blocked from registration with the state’s DMV,” according to California law.

Sundance, at Conservative Treehouse, expands on this, explaining that the EPA reached an agreement with the California Air Resource Board...“The requirement is to purchase electric trucks which do not exist.”

...to shut down semi tractor rigs that were non-compliant with new California emission standards. [snip] In effect, what this 2020 determination and settlement created was an inability of half the nation’s truckers from picking up anything from the Port of LA or Port of Long Beach. Virtually all private owner operator trucks and half of the fleet trucks that are used for moving containers across the nation were shut out.

That’s Problem No. 1.In an effort to offset the problem, transportation companies started using compliant trucks (low emission) to take the products to the California state line, where they could be transferred to non-compliant trucks who cannot enter California. However, the scale of the problem creates an immediate bottleneck that builds over time. It doesn’t matter if the ports start working 24/7, they are only going to end up with even more containers waiting on a limited amount of available trucks.

Problem No. 2, again according to Green, is California’s infamous AB-5, the law that, as a sop to the Democrats’ beloved unions, killed the gig economy:

“Traditionally the ports have been served by Owner Operators,” Oakley says, who are non-union. But under AB-5, “California has now banned Owner Operators.”

(Incidentally, Green says that AB-5’s language is included in the “Build Back Better” bill in Congress.)Just like the union longshoremen, union truckers work under a whole host of work rules that simply can’t accommodate crisis conditions like the ones in Los Angeles.

All of this means that Biden’s grandstanding about having the ports operate 24/7 won’t make a difference. The greenies and the unions killed the infrastructure to unload those ships, with COVID restrictions, trucking restrictions, and free money landing the coup de grâce that led to this situation. Biden does have the emergency power to order those California laws in abeyance, but you know he’s not going to do so.

But of course, the more serious underlying problem is that, in a distant, wonderful past, America didn’t need to rely on containers from Asia to fill her store shelves and Christmas stockings. America was a manufacturing dynamo that fulfilled American needs and still had enough left over for the rest of the world. Those things were well-made, too.

Thanks to our Devil’s bargain with communist China, we have no manufacturing sector and are utterly dependent on China, both for things we like and things we need. Biden’s inflationary politics and crackdown on fossil fuels mean that it will be virtually impossible for a renaissance in American manufacturing. Trump tried to stop this situation but China owns so much of America’s political and industrial class that the pushback shackled his presidency and pushed him straight out of the White House.

It's a depressing scenario but the rosy side is that China’s got a problem if America can’t open the door to her products. Add to this the disastrous collapse in China’s real property sector and China may be hurting as badly as we are.

marsh

On TB every waking moment

Zerohedge

ZeroHedge - On a long enough timeline, the survival rate for everyone drops to zero

Global Ship Backlog Just Got Even Worse As New Supply Chain Nemesis Emerges

THURSDAY, OCT 14, 2021 - 11:40 PM

As if relentless, fiscally-stimulated global demand for (made in China) products, coupled with soaring input prices, Covid-crippled indutries, production-throttling energy crises and containership parking lots off major ports wasn't enough to cripple global supply chains, we can throw in one more factor that will make "just in time" deliveries a thing of the pre-Biden past and will ensure that nobody gets their presents this Christmas.

The weather.

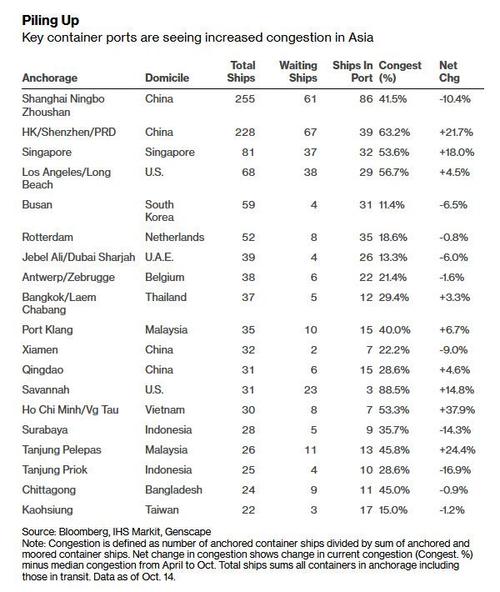

A tropical storm that’s lashing southern China is causing a ship backlog from Shenzhen to Singapore, Bloomberg reports as it warn of even emptier store shelves come Christmas.

Shipping data compiled by Bloomberg show there are currently 67 container ships anchored off Hong Kong and Shenzhen, 22% more congested than median daily counts from April through Oct. 14. Another 61 remain anchored off China's massive Ningbo port in Shanghai.

Container ship positions as of Oct. 14 heatmapped in yellow.

Container ship positions as of Oct. 14 heatmapped in yellow.For once there is no "unintended consequence" behind this pile up - it's the result of Typhoon Kompasu freezing transit lanes, closing schools in Hong Kong and canceling stock market trading in the financial hub on Wednesday. It also sparked the latest containership domino-effect at the worst possible time, with 37 ships now waiting off Singapore, 18% more congested than normal. And with Singapore one of the most efficient ports in the world and a key hub for containers to be moved from one vessel to another while in transit, any disruption in the city-state is bound to have far-reaching ramifications.

The incremental delays will make an already fragile supply chain, that much more unstable: according to the Busan Port Authority in South Korea, vessels are having to wait about three days to berth and that’s causing so-called transshipment cargo to pile up. Meanwhile, almost 40 ships are anchored off Los Angeles, 4.5% more congested than usual, while 11 are cooling their heels off the coast of Malaysia at Tanjung Pelepas, creating a congestion rate about 25% above the median. For Vietnam’s dual hub of Ho Chi Minh City and Vung Tau, things are even worse, with current congestion 38% higher than the median.

Operators are scrambling to find a solution to this chaos which seems to get worse with every passing day: “shipping companies and other stakeholders are trying to resolve the backlog because there are real concerns that many year-end holiday goods will never reach consumers in time,” said Um Kyung-a, an analyst at Shinyoung Securities in Seoul. “This month will be the most challenging period but hopefully things will start to ease from the fourth quarter.”

This is a "hopeful" line we have heard every month since May. It has yet to come true.

Located at the gateway - both literal and metaphorical - of global Transpacific supply chains, accessible port terminals are an indispensable anchor to any hopes of normalizing supply chains. Alas, congestion at container terminals around the world has added pressure to already stretched supply chains. Covid-19 cases at ports, along with shortages of shipping containers and labor have aggravated the problem as exporters try to send goods to the U.S. and Europe before the end of the year.

According to Singapore Logistics Association chairman Dave Ng, vessels are waiting one to three days to berth at most major ports in Southeast Asia, including Singapore, The wait is more than three days at major ports in Northeast Asia and could extend to over a week in other parts of the world. And any incremental delays only cascade exponentially, adding more days to an already broken system.

“Global port congestion has introduced more uncertainty into planning and booking of sea shipments,” Ng told Bloomberg. “Ocean freight costs have increased five to six times from the levels pre-Covid and this has translated into higher operating costs for logistics companies.”

Logistics companies have been working to improve business productivity by sharing resources and leveraging technology, Ng said. But they still face difficulties in filling jobs, particularly driving and warehousing, which could impact operations in the near term, he said.

Meanwhile, Bloomberg reported this week that shipping giant Maersk said earlier this week that it’s diverting some ships from the U.K.’s largest container port because of congestion tied to a trucker shortage. Many logistics companies are finding it difficult to find drivers to pick up and deliver containers, causing a backlog at the Port of Felixstowe.

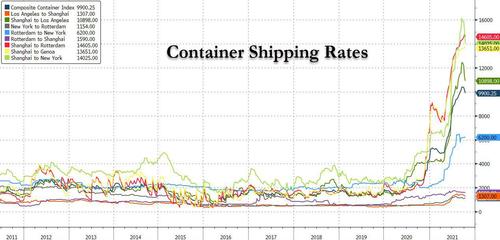

Port congestion and lack of containers has driven shipping rates to record levels this year. Spot levies to haul a 40-foot container to Los Angeles from Shanghai peaked at $12,424 last month before easing to $11,173 as of Oct. 7, the Drewry World Container Index show. Rates to Rotterdam from Shanghai hit an all-time high of $14,807 last week. Shipping rates dipped modestly in the latest week, but as we explained previously, this was for the worst possible reason namely a sharp drop in China output. Expect a sharp spike in the next few weeks as throttled Chinese production returns.

Exporters and shipping companies have been trying to find alternative routes to avoid the backlog. Some cargo from China is now being shipped to Busan and then reloaded on ships bound for Russia’s east coast before being put on trains and sent through to Europe.

In an act of sheer desperation, the Biden admin announced on Wednesday that the Port of Los Angeles will begin operating 24 hours a day, seven days a week as part of efforts to break the logjam. However, as Rabobank explained earlier this morning, simply getting containers out of the terminal at LA achieves very little if you don’t the solve chassis crisis; if the containers sit there waiting for trucks; or for truckers; or for rail. All you do is move the logjam from sea to shore - and that can potentially make matters worse. The Transportation Secretary running this task force is a vocal opponent of the ‘so build a bigger road’ mentality that ends up with bigger roads and the same traffic logjam.

marsh

On TB every waking moment

Zerohedge

ZeroHedge - On a long enough timeline, the survival rate for everyone drops to zero

Alabama School Districts Hit With Food Shortage, Warn Of Remote School Days

FRIDAY, OCT 15, 2021 - 08:10 PM

A school district just north of Montgomery, Alabama, informed parents in a Facebook post that their food vendors are experiencing "supply chain issues" that have led to no food deliveries, and some area schools might not be able to feed kids, according to The Birmingham News.

Alexander City Schools urged parents to feed their children before school or bring snacks due to the lack of food at schools.

"As you know, breakfast and lunch is served daily in our schools. In previous weeks we have not received our food deliveries due to suppliers who are short on supplies, drivers and even warehouse employees," school officials said in a Facebook post on Saturday.

Alexander is experiencing various challenges that stretch from farm to cafeteria table. Food and labor shortages impact everything from food production to transportation to even serving up meals at schools."Breakfast may be impacted more so than lunch in the coming weeks. If possible, we ask that you feed your student breakfast prior to school or try to send a snack," the officials continued.

Alexander is not an isolated issue. School districts across the state are facing similar shortages to varying degrees.

Dothan City Schools, located in the state's southeastern corner, have already notified parents of the possibility that remote school days are possible. The school system must close schools to rebuild depleted inventories of food.

Snarled supply chains have upended other school districts across the country, including ones in Wisconsin and Indiana."As a last resort, we may also ask that you prepare to have virtual/remote school days a few days out of the week to alleviate the stress of our food supplies," the district told parents on Sept. 23."We face a situation where we must do everything we can to continue providing a nurturing environment for our students to learn and grow."

The problem appears to worsen over the last month as some schools are preparing to close down and return to remote learning for other reasons than the pandemic.

marsh

On TB every waking moment

Zerohedge

ZeroHedge - On a long enough timeline, the survival rate for everyone drops to zero

Here's The Truth Behind Biden's 24/7 Port Operations Pledge

FRIDAY, OCT 15, 2021 - 07:10 PM

Written by Lori Ann LaRocco, author of: “Trade War: Containers Don’t Lie, Navigating the Bluster” (Marine Money Inc., 2019) “Dynasties of the Sea: The Untold Stories of the Postwar Shipping Pioneers” (Marine Money Inc., 2018). First published on FreightWaves

When you tear away the frills of President Biden’s supply chain announcement, it is essentially a political pawn to push the infrastructure bill. The ugly truth is the congestion will not be alleviated anytime soon and it will definitely not be any better in the next 90 days. Why?

It’s common sense and math.

You can’t blame private-sector companies for this plan’s future letdown. Trade takes people and coordination among all the players within the supply chain. The ports and all of the stakeholders within these ports must be on the same page when it comes to a 24/7 operation.

The holes in this announcement are numerous.

First, 3,500 additional containers moved in a week is 200 containers a day. During the month of August, the San Pedro Bay ports moved 1,241,896 TEUs. This projection of 3,500 does not move the needle at all. That’s a mere 14,000 containers — which translates into just 1% of the total TEUs. This plan is being called a “sprint.”

Biden’s announcement of 24/7 ports is not accurate. Only one terminal out of the 12 in San Pedro is operating 24 hours a day — Total Terminals International (TTI) at the Port of Long Beach — and that every-second schedule is only Monday through Thursday, making it a 24/4 situation, not 24/7.

A Port of Long Beach official said discussions were taking place with other terminals. But as of now, no other terminals have signed on. In the pursuit of 24/7, you need all the players to make this successful.

The 24/7 operation at the Port of Los Angeles is not even happening. When asked if the port was going 24/7 on Thursday, the day after this announcement, the port press office answered in an email:

“No(t) one marine terminal will go 24/7 tomorrow. This [is] a process to work the details of expanded hours leading to around-the-clock work in the private sector.

It will take all private- and public-sector partners to operationalize this. There are no fast levers, but we have more cargo than ever and need to move it safely and securely. Gene [Seroka, executive director] will be meeting with industry associates tomorrow on this. No ETA as of today.”

So the ports as of right now are status quo as it relates to expanded operations.

The reason for this lack of 24/7 is because every facet of the supply chain must be participating in an equal fashion. Truckers are not going to work 24/7 if they can’t pick up containers at a warehouse that is closed. The flow of trade moves when everyone in that flow is working. The question is what can be done to change the behaviors of those in the supply chain to go to 24/7?

This frustration can be read in a press release from the Harbor Trucking Association, which said the Biden administration’s plan did not address the core issues that have been plaguing the supply chain.

The release stated,

The HTA said thousands of empty containers currently are sitting in motor carrier yards on top of the chassis, preventing those chassis from moving an import container off the dock.“While steamship lines and their marine terminal partners have been pointing the finger at the trucking industry for not utilizing appointments during this crisis, the underlying causes have continued to compound unchecked. Challenges faced by truckers doing business at the ports stem from productivity and efficiency issues that are not alleviated by merely shifting to 24/7 gate operations.”

Also in this plan FedEx, UPS and Walmart were mentioned in stepping up in helping alleviate the supply chain.“So those appointments go unused. … This is not an issue of unwillingness to pick up cargo, the entire supply chain wants this cargo moved. It is instead a tangled web of shifting constraints that impede and discourage participation,” the statement read.

When asked for specifics, FedEx global media relations responded:

Walmart spokesperson Ashley Nolan said:“FedEx Logistics President and CEO Dr. Udo Lange appreciated the opportunity to join other business leaders and the administration to share our expertise and discuss supply chain issues, but we have no other details to share at this time.”

At the time of publication, UPS did not respond to comment.“We’ll increase throughput by as much as 50% during the nighttime hours being added at the port.”

In the sea of faces of those attending this press event, a critical piece of the supply chain was missing — the ocean carriers and the port terminals.

When Transportation Secretary Pete Buttigieg’s office was asked why there was no participation, the response was vague:

And yet, at least one of those carriers has not been contacted — Hapag-Lloyd, one of the largest ocean shipping lines in the world.“The administration has and will continue to have a regular dialogue with ocean carriers and terminal operators.”

The carriers and the terminal operators are key pieces to this puzzle. The terminals are the key segment of the supply chain that not only schedules the truck container pickups and drop-offs, they also request the labor to unload the vessels.“We have not been approached,” confirmed a company spokesperson.

“Ships are already operating 24/7 whenever possible. The challenge is to get containers off the terminal by truck and rail because the warehouses will not/cannot take deliveries on weekends. It is a lot about shippers’ inability to take delivery of their goods and infrastructure bottlenecks in the U.S.”

So if this is a 90-day sprint, the U.S. supply chain needs more muscle and a massive shot of adrenaline.

SurvivalRing

Rich Fleetwood - Founder - author/coder/podcaster

Came across this story this afternoon… thanks for posting it here…I was just about to.

The California Version of The Green New Deal and an October 16, 2020, EPA Settlement With Transportation is What's Creating The Container Shipping Backlog - Working CA Ports 24/7 Will Not Help, Here's Why - The Last Refuge

Hundreds of requests for details on the specifics of the container shipping backlog. So, I spent 3 days calling sources, digging for details and gathering information on the substantive issue at hand. The epicenter of the problem is not what is being outlined by financial media, corporate...theconservativetreehouse.com

The California Version of The Green New Deal and an October 16, 2020, EPA Settlement With Transportation is What’s Creating The Container Shipping Backlog – Working CA Ports 24/7 Will Not Help, Here’s Why

October 14, 2021 | Sundance | 573 Comments

Hundreds of requests for details on the specifics of the container shipping backlog. So, I spent 3 days calling sources, digging for details and gathering information on the substantive issue at hand. The epicenter of the problem is not what is being outlined by financial media, corporate media and politicians who have a specific interest in distracting from the issues at hand. This has nothing to do with COVID-19.

The issues being discussed today relate to events that happened a long time ago. As a matter of fact, it was so predictable that Amazon, Walmart, UPS, FedEx, Samsung, The Home Depot and Target all had taken actions years ago -long before COVID- because they knew this day would come. It was not accidental that those companies showed up at the White House to discuss the issue, because there’s now a full court press to hide it.

There is one very specific regional issue driving the problem. Read on:

The trucking issue with California LA ports, ie the Port of Los Angeles (POLA) and the Port of Long Beach (POLB), is that all semi tractors have to be current with new California emissions standards. As a consequence, that mean trucks cannot be older than 3 years if they are to pick up or deliver containers at those ports.

This issue wipes out approximately half of the fleet trucks used to move containers in/out of the port. Operating the port 24/7 will not cure the issue, because all it does is pile up more containers that sit idle as they await a limited number of trucks to pick them up. THIS is the central issue.

On October 16, 2020, the EPA reached a settlement agreement [DATA HERE] with California Air Resource Board (CARB) to shut down semi tractor rigs that were non-compliant with new California emission standards:

2020 SAN FRANCISCO – “Today, the U.S. Environmental Protection Agency (EPA) announced settlements with three interstate trucking companies imposing $417,000 in penalties for violating the California Air Resources Board’s federally enforceable Truck and Bus Regulation, Drayage Truck Regulation and Transport Refrigeration Unit Regulation.

“As trucks are one of the largest sources of air pollution in California, EPA will continue to ensure these heavy-duty vehicles have the needed pollution-control equipment and operate in compliance with the rules,” said EPA Pacific Southwest Regional Administrator John Busterud. “These companies have agreed to bring their trucks into compliance and operate more cleanly in all communities they serve.”

Transportation is a primary contributor to the high levels of air pollutants in Southern California and the Central Valley. Diesel emissions from trucks are one of the state’s largest sources of fine particle pollution, or soot, which is linked to health issues including asthma, impaired lung development in children, and cardiovascular effects in adults. Many of these trucks are older models and emit high amounts of particulate matter (PM) and nitrogen oxides (NOx).

[…] California Truck and Bus Regulation and Drayage Truck Regulation have been essential parts of the state’s federally enforceable plan to attain cleaner air.

California requires trucking companies to upgrade vehicles they own to meet specific NOx and PM performance standards and to verify compliance of vehicles they hire or dispatch. Heavy-duty diesel trucks in California must meet 2010 engine emissions standards or use diesel particulate filters to reduce the diesel particulates emissions into the atmosphere by 85% or more. (read more)

In effect, what this 2020 determination and settlement created was an inability of half the nation’s truckers from picking up anything from the Port of LA or Port of Long Beach. Virtually all private owner operator trucks and half of the fleet trucks that are used for moving containers across the nation were shut out.

In an effort to offset the problem, transportation companies started using compliant trucks (low emission) to take the products to the California state line, where they could be transferred to non-compliant trucks who cannot enter California. However, the scale of the problem creates an immediate bottleneck that builds over time. It doesn’t matter if the ports start working 24/7, they are only going to end up with even more containers waiting on a limited amount of available trucks.

Yesterday, in an effort to obfuscate and actually hide the epicenter of the issue, the White House put on a performance to provide political cover. In a grand pantomime, Joe Biden met with the heads of the Ports of Los Angeles and Long Beach (Gene Seroka and Mario Cordero, respectively), and the International Longshore and Warehouse Union (ILWU).

The publicized meeting and White House conference was sold as Biden and Transportation Secretary Pete Buttigieg showing actions they are taking to address delays and congestion across the transportation supply chain in Southern California.

As a result of the meeting, the Port of Los Angeles (POLA) announced that it will join the Port of Long Beach (POLB) in expanding to 24/7 operations. POLA will add new off-peak nighttime shifts and weekend hours, nearly doubling its hours of operation. The ILWU said its members are willing to work those extra shifts to add needed labor capacity.

That publicly promoted action event was a complete political farce. No amount of extra productivity in working the docks to off-load ships will solve the issue of trucks that cannot pick up the containers and distribute them toward manufacturing or warehouses.

As I noted, the issue started becoming visible several years ago when the California Air Resource Board (CARB) announced the new environmental regulations. Several massive multinational corporations, with specifically in-tune supply and logistics operations, immediately recognized the issue they would face if 50+ percent of the trucking fleet would be blocked from entering California ports.

Yes, years ago the private sector predicted this would happen, and they started taking actions to protect their supply chains. What these massive corporations did to reduce their exposure to supply chain disruption was to immediately formulate plans to divert their goods to other ports. This was a very expensive shift in supply chain and logistic efforts for these massive corporations, which includes: Amazon, Walmart, UPS, FedEx, Samsung, The Home Depot and Target.

A long time before and during the era of the Trump administration, those massive multinational corporations knew they would need to redirect their import cargo quickly to avoid the bottleneck caused by California’s new emission standards. They began organizing new destination ports for their products and began setting up new hubs and distribution networks to avoid the predictable California port bottlenecks.

Obviously, for politically correct reasons; and in an effort to avoid the woke mob of environmentalist jackboots, the corporations didn’t publicly share any of the issues they could foresee coming – they just worked independently and quietly to avoid the issue.

However, it costs more money to move and entire supply chain for trillions of tons of goods coming. Hence, we saw prices climbing as a result of increased transportation costs being factored in to the new logistics. Did you hear about massive increases in container shipment prices? Well, THAT’S WHY. The entire supply chain from Asia to the United States was being modified from the closest port (California) to the ports where internal transportation would not be an issue.

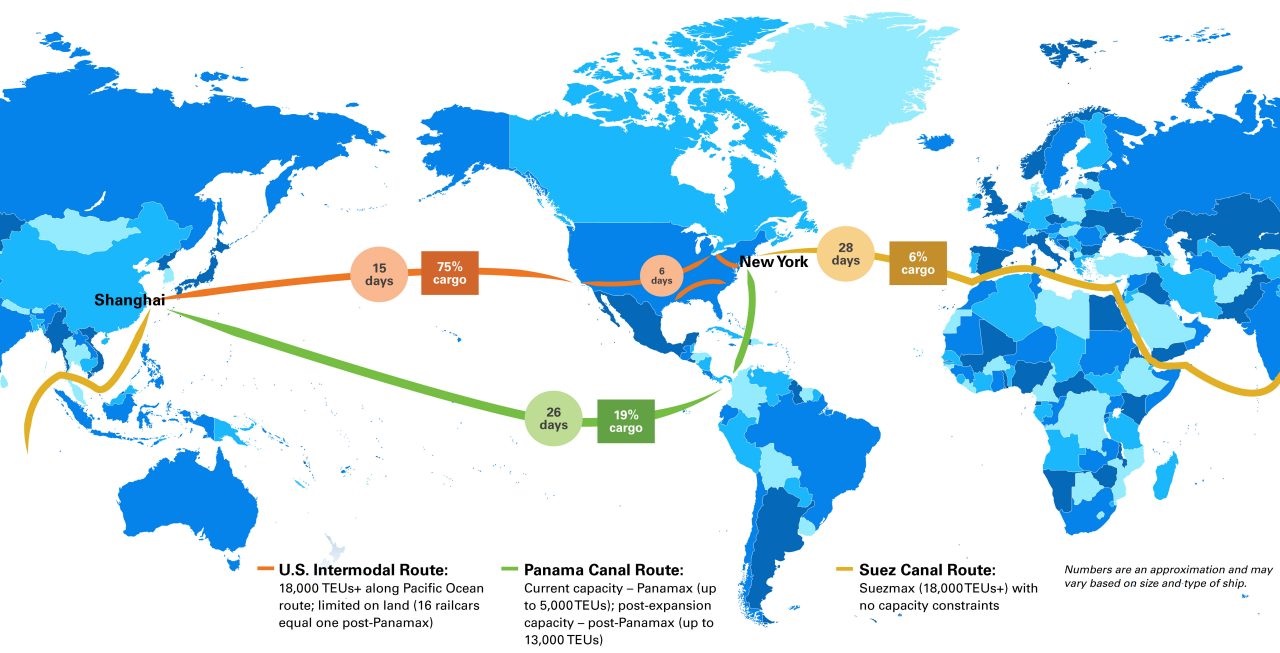

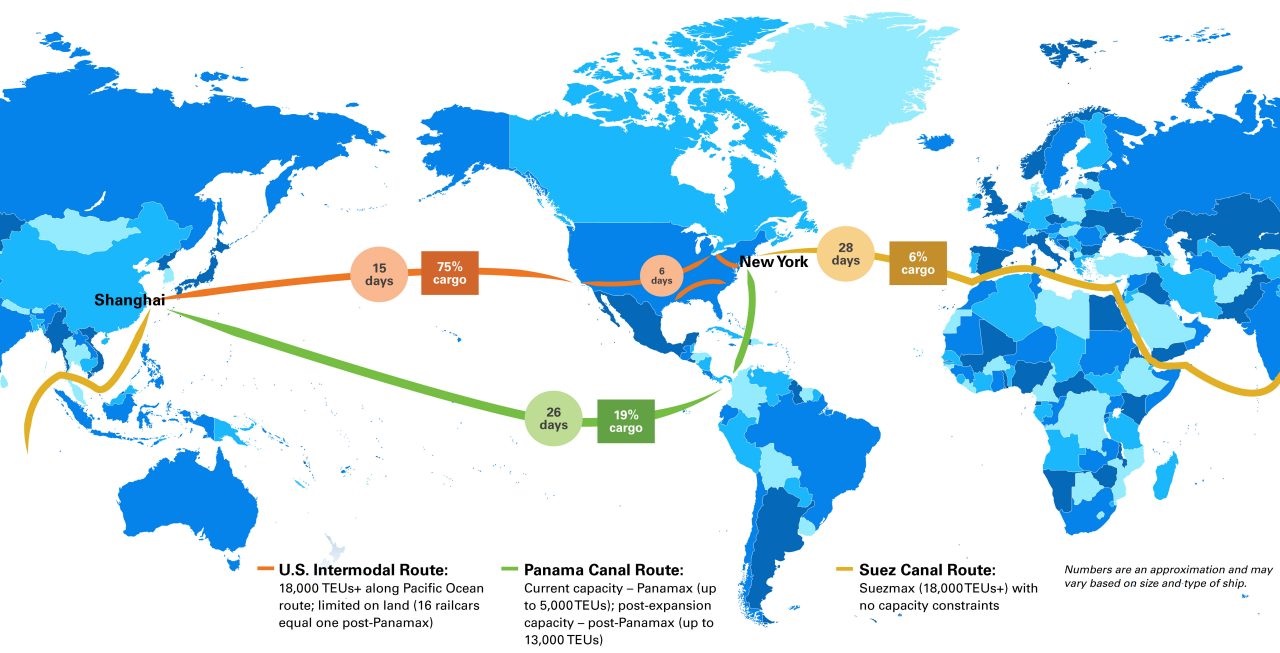

Ships from China and SE Asia being diverted from California into the Gulf of Mexico or East coast have to go through the Panama Canal. It takes twice as long and costs twice as much, if not more. Hence, massive shipping price increases:

Unfortunately, small companies and small brokers of import goods do not have the control over their part of the supply chain from Asia to the West Coast. They don’t contract for entire cargo ships with thousands of containers. Those wholesalers, brokers and smaller companies that feed raw material and parts supplies to manufacturing and smaller retail outlets are stuck waiting for their containers to get through the trucking issue in California.

The bottleneck at the Ports of Los Angeles and Long Beach run by Gene Seroka and Mario Cordero is not caused by a lack of longshoremen and dock workers to off-load the vessels. The bottleneck is caused by half of the previous trucks used to enter the ports and pick up containers not being allowed. Factually, it doesn’t make a tinkers damn worth of difference if the port works 24/7/365. The ports are simply running out of space.

The ports are running out of places to store containers full of goods that are getting off-loaded. Hundreds of thousands of them are piling up. The central issue is the inability of emission compliant heavy transportation in California to move those containers full of goods to manufacturing, warehouses and distribution points.

This California bottleneck has been building, and building and building for years, until now it has reached a crisis point.

If you want to know how long this has been taking place, take the time to watch this video of a trans-continental shipment belonging to Amazon Inc from China. As you watch this really good discussion, think about how long Amazon Inc. has known about the problem in order for them to have put such a massive solution into place in order to avoid California.

Yeah, this California emissions issue has been identified for years, and Amazon has been planning to avoid it for years. WATCH:

View: https://youtu.be/gsBIQIBavms

20:40 min

THIS … is the heart of the problem…the lack of incoming food, appliances, raw materials, computer chips. Hell, EVERYTHING we are quickly running out of.

This is the bottleneck, and California is reason for the problem every American is now facing…staring down the barrel of an intentional shotgun…aimed at every one of us.

This falls DIRECTLY into Piglosi’s lap…and as every single one of us know, she is directly behind this Armageddon…and every single empty shelf in America.

marsh

On TB every waking moment

California has been busy implementing the Green New Deal. Many of the Green provisions that made it into law here are copied and pasted into the federal Dem legislation (either budget or infrastructure.)

They aren't learning the consequences of this crap ideology, just replicating it.

I don't think there is much doubt left that they want to decivilize us by Christmas.

They aren't learning the consequences of this crap ideology, just replicating it.

I don't think there is much doubt left that they want to decivilize us by Christmas.

marsh

On TB every waking moment

With 'Mayor Pete' on Paternity Leave, Biden Chooses Navy Climate Change Expert with No Commercial Shipping Experience to Address Shipping Crisis | The Gateway Pundit | by Joe Hoft

Biden’s Secretary of Transportation, ‘Mayor Pete’ Buttigieg, is out on paternity leave. So Biden chooses a US Maritime Administrator with zero experience on commercial ships to address the largest shipping crisis in the country’s history.

With ‘Mayor Pete’ on Paternity Leave, Biden Chooses Navy Climate Change Expert with No Commercial Shipping Experience to Address Shipping Crisis

By Joe Hoft

Published October 16, 2021 at 8:10am

Biden’s Secretary of Transportation, ‘Mayor Pete’ Buttigieg, is out on paternity leave. So Biden chooses a US Maritime Administrator with zero experience on commercial ships to address the largest shipping crisis in the country’s history.

We reported last month on the ships anchored offshore unable to unload their cargo from overseas.

Yesterday we reported that the Secretary of Transportation, the individual who should be addressing this mess, is out on paternity leave in the greatest commercial shipping crisis history.

Now gCaptain reports:

…during the worst shipping crisis of the century, the US Department of Transportation, has appointed someone to the US Maritime Administration (MARAD) who is not a captain and has no commercial shipping experience.

…[on Thursday] Biden announced his intention to nominate Rear Admiral Ann Phillips, US Navy (Retired), as the next US Maritime Administrator…

Phillips is a highly decorated Navy leader with a long list of accomplishments and is highly respected by everyone gCaptain has interviewed. She was head of the Navy’s Climate Change Task Force and is a highly sought after consultant on climate security issues. She holds an MBA. She was chairman of a local government Sea Level Rise Preparedness and Resilience project. She once captained a Navy warship. The appointment looks great on paper except for one kinda big problem. This is not a warship position. It’s a commercial shipping appointment and she has zero experience aboard any commercial ships. She does not even have experience leading navy military sealift ships.

The position of US Maritime Administrator is traditionally held by a commercial shipowner or captain, but President Obama left the position unfilled for years then selected a former congressional staffer, David Matsuda. He was highly unpopular and was pushed out in 2013.

Obama followed the appointment with a relatively low ranking navy submarine commander Chip Jaenichen.

The Trump administration appointed US Navy Rear Admiral Mark Buzby for the position. Buzby, while not a commercial mariner or ship owner, was a graduate of the US Merchant Marine Academy (USMMA), ran sealift operations for the Navy, was on the board of directors of Carnival Cruise Line, and spent his first year traveling around the country, meeting with ship captains and commercial maritime stake holders. He reached out and listened to stakeholder needs. Buzby became highly popular within the industry on his promise to publish a new US Maritime Strategy to resuscitate the US Merchant Marine. He did write that strategy but it was lost in the malaize of government bureaucracy.

gCaptain continues:Mark Buzby did, however, accomplish one seemingly impossible task, he saved Aker’s Phillidelphia Shipyard from closing by purchasing four new state maritime academy training ships (NSMVs), valued at over $1.5 billion. Construction of the NSMVs supports over 1,000 direct shipyard jobs in Philadelphia. Buzby also convinced the US Transportation Command to do a major “turbo-activation” of the Ready Reserve Fleet to prove the abysmal state of our nation’s readiness to move materials for war.

This crisis is Biden and China made.Each action [by Biden] however has been a misstep. To the untrained eye the 139 ships waiting to leave Los Angeles may look like a port crisis that can be solved by a US Port Envoy, it is not. It is a SHIPPING crisis. Numerous ports around the United States including Oakland and San Diego, have extra capacity, what we don’t have is anyone with recent SHIPPING experience at MARAD directing the SHIPS to empty ports. This week Biden addressed the nation with a plan to prevent containergeddon from ruining Christmas but experts say his plan is doomed to fail because, again, not a single ship captain was called to give advice on how to fix this SHIPPING crisis.

marsh

On TB every waking moment

marsh

On TB every waking moment

As Expected Containergeddon is Getting Worse - Biden's Political Solution to Clear The Ships From Los Angeles Ports Only Making Things Worse - The Last Refuge

This is a follow-up to the original explanation of the epicenter of the supply chain backlog issue, ie “The Clog“. {GO DEEP} You need to review the years-long and building background issue to understand the fubar that Joe Biden has just made worse. From the White House perspective, the problem...

As Expected Containergeddon is Getting Worse – Biden’s Political Solution to Clear The Ships From Los Angeles Ports Only Making Things Worse

October 16, 2021 | Sundance | 367 Comments

This is a follow-up to the original explanation of the epicenter of the supply chain backlog issue, ie “The Clog“. {GO DEEP} You need to review the years-long and building background issue to understand the fubar that Joe Biden has just made worse.

From the White House perspective, the problem at the California ports, specifically the Port of Los Angeles (POLA) and the Port of Long Beach (POLB), was visible due to hundreds of container ships sitting in a queue off the coast of Los Angeles awaiting their opportunity to offload their cargo. The media was reporting on the backlog of ships and Joe Biden was under fire.

The team behind Joe Biden wanted the optics removed asap. Hence, the White House meeting with the heads of the Ports of Los Angeles and Long Beach, Gene Seroka and Mario Cordero, respectively.

The continuing supply chain crisis of empty store shelves, missing parts and component goods that are backlogged at the California ports may be politically represented by the optic of those floating vessels. However, that’s not the problem.

The problem is a shortage of CA emission compliant internal transportation trucks to move the containers out of the port and into the U.S. mainland.

As a result… the politically expedient goal to get rid of the optical problem (the ships) by offloading containers into a California port system, that is already overwhelmed with tens-of-thousands of containers, is only making the original issue exponentially worse.

With hundreds more containers being offloaded hourly, the port infrastructure needed to load trucks long-sitting in the queue to pick up containers that arrived weeks ago is collapsing.

Truckers are waiting for over 8 hours to pick up their freight because the yards are swamped with containers. As each hour passes, more containers are offloaded into the port that can no longer deal with the scale of the problem.

Each individual container is now buried in an avalanche of more containers, and that is making the limited compliant trucking resources even more problematic….. “containergeddon“.

Long before the ships started lining up offshore, many massive multinational corporations could foresee what was happening. They diverted their contracted freight into alternative ports (outside California) and began setting up new transportation arrangements. Two things happened:

(1) The alternative ports started getting backed up due to the redirected cargo arriving; and

(2) The shifted Trucking and Railroad system priority now meant resources were pulled from California.

With trucking companies redirecting resources away from California, this exacerbates the California backlog. Suppliers and retailers then enter a bidding war for priority distribution to get their stuff and avoid the clogs. This is a perfect storm of disruption in the supply chain aptly called “containergeddon.”

However, not all ports can offload ships with thousands of containers. Not all ports have massive gantry cranes that can efficiently offload the cargo.

Back in California (where POLA and POLB do have the gantry cranes), now you have Los Angeles port workers saying we are offloading ships at maximum productivity, and truck drivers saying they’ve been sitting around for hours, some even days, waiting to pick up their containers. Meanwhile, other ports outside California are under pressure from the rerouted backlog of container vessels, and a limited amount of resources, trucks and railroad shipments to clear their arrivals.

Port workers are saying it’s not their lack of offloading that creates the problem, and the truckers are saying it ain’t us… “we’re sitting here waiting”.

♦ Few people are paying attention to what actually created the crisis in the first place.

The backlog all comes from California West Coast ports. It’s the issues with the new California emission regulations {Go Deep} that created the regional bottleneck in the distribution pipeline. The growing issue started becoming visible several months/years ago when the California Air Resource Board (CARB) announced the new environmental regulations.

As a direct result, several massive multinational corporations, with specifically concerned supply chain and logical operations specialists, immediately recognized the issue they would face if 50+ percent of the diesel fleet (writ large) would be blocked from entering California ports. That’s why months ago massive corporations began exclusive shipping contracts to avoid the California created crisis:

REUTERS – […] “The dry bulk cargo ship has been drafted into the service of retail giant Walmart, which is chartering its own vessels in an effort to beat the global supply chain disruptions that threaten to torpedo the retail industry’s make-or-break holiday season.

[…] Other big retail players, such as Target, Home Depot , Costco and Dollar Tree, have said they are chartering ships to deal with the … slowdown of sea networks that handle 90% of the world’s trade.” (link)

It costs more money, a lot more money, to move an entire supply chain for billions of tons of goods coming. The increases in shipping costs are passed along to the consumer.

Hence, we see prices climbing as a result of increased transportation costs being factored in to the new logistics. Did you hear about massive increases in container shipment prices? Well, THAT’S WHY.

The entire supply chain from Asia to the United States was being modified from the closest port (California), which was cost effective, to the ports where internal transportation would not be an issue.

Ships from China and SE Asia were being diverted away from California, some through the Gulf of Mexico into Texas, Louisiana, Alabama ports or inland waterways. Some even headed to the East Coast. However, any shipment diverting from the West Coast has to go through the Panama Canal into the Gulf of Mexico. It takes twice as long and costs twice as much, if not more. Hence, massive shipping price increases per container.

Back in Washington DC, Joe Biden’s solution was to get rid of the ships floating off the coast of California by piling their cargo into Los Angeles ports that are already overwhelmed with cargo they are trying to organize. The emission compliant truck drivers are now charging the ports for their time sitting around waiting for the dock workers to locate their freight.

The more containers they pile into the port, the longer it takes a limited number of trucks to move them.

The California ports are running out of places to store containers full of goods that are getting off-loaded. Hundreds of thousands of them are piling up. The central issue is the inability of emission compliant heavy transportation in California to move those containers full of goods to manufacturing, warehouses and distribution points.

This California bottleneck has been building, and building and building for years, until now it has reached a crisis point.

FUBAR.

marsh

On TB every waking moment

GOP Rep. Gimenez: Vax Mandate Will 'Put Our Supply Chain in Real Jeopardy' and Biden Admin. Will 'Have to Back off' on It

On Saturday's broadcast of the Fox News Channel's "Fox & Friends," Rep. Carlos Gimenez (R-FL) said that the federal vaccine mandate will "put our | Clips

GOP Rep. Gimenez: Vax Mandate Will ‘Put Our Supply Chain in Real Jeopardy’ and Biden Admin. Will ‘Have to Back off’ on It

11:16 min

IAN HANCHETT16 Oct 2021154

On Saturday’s broadcast of the Fox News Channel’s “Fox & Friends,” Rep. Carlos Gimenez (R-FL) said that the federal vaccine mandate will “put our supply chain in real jeopardy” and predicted that the Biden administration will end up having to back off on the mandate due to the layoffs it will cause.

Gimenez predicted that the vaccine mandate is “actually going to put our supply chain in real jeopardy. It’s going to make things worse. And I think, you know, my prediction is that the Biden administration’s going to have to back off on this a little bit. Because there are hundreds of pilots and truck drivers and port workers, etc., even first responders that are saying no to the vaccine.”

marsh

On TB every waking moment

Biden Regime Gets DESTROYED By Ex Walmart CEO Over Supply Chain Crisis

As per usual, the White House and Democrats are missing in action as videos circulate showing cargo ships backed up, storage units stacked to the brim,

NEWS AND COMMENTARY

Biden Regime Gets DESTROYED By Ex Walmart CEO Over Supply Chain Crisis

"The supply chain is a mess from start to finish... Other than that, everything is going pretty well.”

BY JEREMY PORTER

OCTOBER 15, 2021

As per usual, the White House and Democrats are missing in action as videos circulate showing cargo ships backed up, storage units stacked to the brim, and supermarket shelves completely bare. Like most of the problems that are put in front of the Biden administration, the dilemma with the supply chains is slowly becoming a full-blown crisis if it isn’t already there. And although Biden is silent, former Walmart CEO Bill Simon spoke to Fox Business Network on Friday, admitting the supply chain is an absolute mess “from start to finish”.

Speaking with Dagen McDowell, the host asked Simon, “Bill, you’re saying you have never seen retail shelves this empty. What are your thoughts on the big picture here?”

With no other way to put it, Simon answered, “I’ve never seen it like this and I don’t think anyone living in this country has. This is really unprecedented. The supply chain is a mess from start to finish. They are backed up in the ports in Asia. They are backed up on the water. They are backed up in the ports in the U.S. as well.”

Simon also revealed that supply shortages don’t just stop at consumer goods. He added, “There’s a shortage of truck drivers, there’s a shortage of labor in our distribution system and there’s a shortage of people to put it on the shelves.”

Trying to find something good to say, Simon did end with, “Other than that, everything is going pretty well.”

https://tv.gab.com/media/6169fbb68f...=fa19575d-d1d4-4739-8b84-52c5bfbb53fb&r=1080p 4:09 min

marsh

On TB every waking moment

Dr. Peter Navarro Discusses How Biden is Driving the Country Towards Stagflation with Massive Spending While Supply Chain Is In Tatters

By Joe Hoft

Published October 17, 2021 at 8:45am

Dr. Peter Navarro is warning the world about stagflation on the horizon as a result of insane Biden policies. He was on Steve Bannon’s War Room to discuss the scenario.

Dr. Navarro was on with Newsmax as well:

Peter Navarro was on with Steve Bannon on his War Room warning about extreme stagflation as well.If it was just inflation affecting the United States, that would be “manageable,” but instead a “stagflation” problem like the one that hit the nation in the 1970s is occurring under President Joe Biden, former White House trade adviser Peter Navarro told Newsmax on Saturday.

Federal Reserve Chairman Jerome Powell is “printing money,” Navarro told “The Count.” “That’s driving us to what we call demand-pull inflation. But then at the same time, we have the pandemic, coupled with the effects of the Biden administration cracking down on fossil fuels, giving us what’s called cost-push inflation.”

But during the Trump administration, “we were the Saudi Arabia of natural gas,” Navarro said. “One of the great triumphs of President [Donald] Trump was strategic dominance. The energy sector had the ability to export petroleum for the first time in 50 years.”

Now, under Biden, energy prices are going up quickly, which also drives up food prices.

“Meanwhile the supply chain is absolutely in tatters,” Navarro said. “When I was in the White House with President Trump it was to buy American, hire American, bring out manufacturing onshore. When you do that, you bring the supply chains onshore and you eliminate that risk of interdiction that we have now when the corporations love to offshore jobs.”

Rumble video on website 13:57 min

The economy is the next major mistake of the Biden Administration and Americans will continue to suffer from this senile tyrant.

^^^^^^^^^^^^^^^

Trucker And Delivery Driver Shortage Freezing Supply Chain 8:19 min

Trucker [Don Aman] And Delivery Driver Shortage Freezing Supply Chain

Bannons War Room Published October 16, 2021

marsh

On TB every waking moment

Buttigieg Says Higher Prices and Supply Chain Crisis "Will Continue Into Next Year" (VIDEO) | The Gateway Pundit | by Cristina Laila

Small town mayor-turned-Transportation Secretary Pete Buttigieg on Sunday said higher prices and supply chain woes will continue into next year.

Buttigieg Says Higher Prices and Supply Chain Crisis “Will Continue Into Next Year” (VIDEO)

By Cristina Laila

Published October 17, 2021 at 11:40am

Small town mayor-turned-Transportation Secretary Pete Buttigieg on Sunday said higher prices and supply chain woes will continue into next year.

Buttigieg has been on extended paid paternity leave since August, his office revealed Thursday night to Politico, finally answering the question of “Where is Mayor Pete?” that has been being asked as the nation is in a supply chain crisis.

A Buttigieg spokesman told Politico that while he is doing some work, Buttigieg intends to “continue to take some time over the coming weeks to support his husband and take care of his new children.”

Buttigieg took some time away from his paternity leave Sunday to answer a few questions about the supply chain crunch on CNN’s “State of the Union.”

Buttigieg told host Jake Tapper that higher prices and supply chain troubles are here to stay for the foreseeable future.

“A lot of the challenges we’ve been experiencing this year will continue into next year,” Buttigieg said.

VIDEO:

marsh

On TB every waking moment

Buttigieg: Supply Chain Troubles 'Will Continue into Next Year'

Secretary of Transportation Pete Buttigieg said Sunday on CNN's "State of the Union" that the supply chain backups at America's ports "will continue into next year." | Clips

Buttigieg: Supply Chain Troubles ‘Will Continue into Next Year’

PAM KEY17 Oct 20211,397

Secretary of Transportation Pete Buttigieg said Sunday on CNN’s “State of the Union” that the supply chain backups at America’s ports “will continue into next year.”

Anchor Jake Tapper said, “We are seeing supply chain disruption causing everything from higher prices to longer waits for products. Moody’s warns that these supply chain disruptions, quote, ‘will get worse before they get better, ‘ unquote. do Americans need to prepare ourselves for this to get worse before it gets better?”

Buttigieg said, “Certainly, a lot of the challenges that we have been experiencing this year will continue into next year. But there are both short-term and long-term steps that we can take to do something about it. Part of what’s happening isn’t just the supply side. It’s the demand side. Demand is off the charts.”

Tapper said, “Many American companies, especially small businesses, as you note, are struggling to cope. One possible solution, President Biden lifting former President Trump’s tariffs on China to try to provide some relief. That’s not a panacea, but it could provide some relief. Will President Biden do that?”

Buttigieg said, “Every idea is being taken seriously. What we’re doing right now is to focus on the operations themselves. A lot of Americans might be surprised to learn our ports have not generally operated on a 24/7 basis. We have secured commitments to change that. The president announced that the ports of LA and Long Beach — Long Beach was piloting this for a few weeks. Collectively, those two ports are 40% of our container traffic. They’re now going 24/7. That’s not a simple thing to do overnight. It was a big commitment.”

marsh

On TB every waking moment

Lazy crane operators making $250,000 a year exacerbating port crisis, truckers say

LONG BEACH, California — Crane operators who belong to a powerful union and earn up to $250,000 a year transferring containers from ships to trucks are worsening the supply chain crisis that threatens Christmas by goofing off on the job, frustrated truckers told the Washington Examiner.

Lazy crane operators making $250,000 a year exacerbating port crisis, truckers say

Lazy crane operators making $250,000 a year exacerbating port crisis, truckers say

Tori Richards

Fri, October 15, 2021, 1:01 PM·6 min read

In an aerial view, container ships and shipping containers are seen at the Port of Los Angeles on September 20, 2021 near Los Angeles, California. Mario Tama/Getty Images

LONG BEACH, California — Crane operators who belong to a powerful union and earn up to $250,000 a year transferring containers from ships to trucks are worsening the supply chain crisis that threatens Christmas by goofing off on the job, frustrated truckers told the Washington Examiner.

The finger-pointing at the busy Los Angeles County ports comes as scores of container ships are anchored off the California coast, waiting in some cases for weeks to unload their freight. The Biden administration has scrambled to get shipping executives, port officials, and labor to tackle the problem. While the reasons for the burgeoning backlog are complex, truck drivers say not everyone seems to be working together.

“In 15 years of doing this job, I’ve never seen them work slower,” said Antonio, who has spent hours waiting at Los Angeles County ports for cargo to be loaded.

“The crane operators take their time, like three to four hours to get just one container. You can’t say anything to them, or they will just go [help] someone else.”

The Washington Examiner spoke to six truck drivers near the Long Beach/Terminal Island entry route, and each described crane operators as lazy, prone to long lunches, and quick to retaliate against complaints. The allegations were backed up by a labor consultant who has worked on the waterfront for 40 years. None of the truckers interviewed for this story wanted to provide a last name because they fear reprisals at the ports.

The crane operators are part of the International Longshore and Warehouse Union, which also represents longshoremen. Veteran operators who have a set schedule make approximately $250,000 a year, while others who receive daily work assignments make $200,000, said labor consultant Jim Tessier, who represents longshoremen in disputes against the union.

A Hong Kong cargo ship is unloaded in Long Beach harbor. Tori Richards

“What you are talking about is perfectly described behavior,” Tessier said of the crane operators. “This is all a reflection of the management they have down there, the inmates run the asylum. The managers are all afraid to say anything because the operators are so powerful they get management fired if they don’t like them.

”

Most truckers are independent contractors who are paid per container delivery and make a fraction of a crane operator's salary. They only arrive at the docks after receiving notification that the cargo is ready for pickup. Waiting hours for shipping containers to be loaded onto their trucks is frustrating, and those who have complained were swiftly dealt with, they say.

“They’ll go get the police and kick you out and tell you to leave,” said trucker Chris. “Then, you get banned from coming back in there.”

Or sometimes, the crane operator will mete out punishment by skipping the trucker and working on someone else, exacerbating the wait.

While three-hour waits are common, some truckers have been at the port for days.

“They will wait there all day and then come back the next day,” Chris said. “I know someone who kept coming back, and eventually, [the terminal] will charge you a storage fee if you don’t get the container out of there.”

Truckers unlucky enough to be waiting around lunchtime will watch as the entire crane crew stops work, instead of staggering their hours.

“They leave for two hours, and you are stuck with no one there,” trucker Brian said.

Jennifer Sargent Bokaie, Communications Director of ILWU CLD told the Washington Examiner: "ILWU dockworkers have been busy moving cargo at historic rates.

"The Port of Los Angeles broke two Western Hemisphere cargo volume records – one in May when it processed over 1 million TEUs – representing the ports busiest month in its 114 year history, and the other for moving over 10 million TEUs in a single year.

"In addition to the work taking place at the Port of Los Angeles, the Ports of Long Beach, Oakland, and the Northwest Seaport have also broken records throughout the summer and continue today to move cargo as quickly as the off-port supply chain will allow. As you can imagine, ILWU dockworkers are extremely proud of these accomplishments and their contributions to keeping our economy strong and nation moving forward."

As of Wednesday, 59 ships were at a berth unloading cargo at one of the three Los Angeles ports. Another 88 are anchored off the coast stretching along Orange County and around Catalina Island, according to the Marine Exchange, which coordinates the ship traffic. The wait time to come into port can be weeks, including one ship that has been in a holding pattern miles offshore since Sept. 9.

The backlog, stretching 20 miles along the coast, has forced many large retailers to circumvent the bottleneck and charter their own ships so products can be on shelves before the Christmas shopping season. Reuters reported that incoming cargo is up 30%, which is also part of the problem.

A secondary issue leading to the crunch is a lack of available chassis at the ports to place the cargo containers onto before they're hauled away by the truckers.

While the truckers say they are making the same number of trips as previous years, for some reason, chassis are in short supply for those who don't own one, and they wait for returns to come in.

In an effort to clear the logjam, President Joe Biden negotiated a 24-hour port operation. One of Long Beach’s terminals has already been working around the clock. The Port of Los Angeles and the Port of Long Beach account for roughly 40% of all U.S. imports.

But the round-the-clock schedule probably won’t matter much because the crane operators work slower at night, said a trucker identified as Oscar.

“Compared to all the other years, they are definitely [working] slower now. I wait at least three hours every single day,” he said. Oscar makes two trips to the ports a day to pick up shipping containers full of electronics, which are dropped off in the greater Los Angeles area — a 10-hour process.

Oscar said each terminal has two massive cranes to load cargo and he’s never seen both of them operating at once. A survey of two dozen cranes in Long Beach by the Washington Examiner found at least half of them nonoperational.

However, one terminal in Long Beach has started using automated cranes, and truckers rejoice when they are summoned to pick up cargo there. It is efficient and quick.

“They have to hire extra men to work the cranes and don’t want to do it,” Tessier said. “There are a lot of things [terminal operators] could do but don’t do because it costs extra money. Shows how concerned they are about their customers.”

Donghe Surfer

Veteran Member

Fuq Kalifornia.

As Expected Containergeddon is Getting Worse - Biden's Political Solution to Clear The Ships From Los Angeles Ports Only Making Things Worse - The Last Refuge

This is a follow-up to the original explanation of the epicenter of the supply chain backlog issue, ie “The Clog“. {GO DEEP} You need to review the years-long and building background issue to understand the fubar that Joe Biden has just made worse. From the White House perspective, the problem...theconservativetreehouse.com

While I fully support the truckers, longshoremen, etc., I hope this really screws Kali and D.C. up the wazoo.

The more containers that pile up onshore, and the less they get found by U.S.-based logistics, the happier I'll be.

I've been ready for this kind of fubar to happen for a long time.

It's now happening, and I don't give a sheet if Christmas goes back to being something that people celebrate together with just church, songs, and a few homemade gifts.

marsh

On TB every waking moment

Blame Government, Not COVID-19, for Supply Chain Collapse

Having made a mess of Afghanistan, the Biden administration now turns its trademark incompetence to something closer to home; namely, the supply chains that put toys under our Christmas trees and food on our tables. Biden is using the pandemic as an excuse, but the truth is that government...

americanconservativemovement.com

americanconservativemovement.com

Blame Government, Not COVID-19, for Supply Chain Collapse

by Peter St. Onge

October 17, 2021

Having made a mess of Afghanistan, the Biden administration now turns its trademark incompetence to something closer to home; namely, the supply chains that put toys under our Christmas trees and food on our tables.

Biden is using the pandemic as an excuse, but the truth is that government diktats, handouts, and cronyism have catastrophically gummed up our supply chains, and it’s getting worse.

In response to rising criticism about his absent administration amid “bare-shelves Biden” trending online, the president bestirred himself on Oct. 13 to trumpet a Band-Aid, while his transportation secretary smirks about late shoppers and predicts shortages may last “years and years.”

Contrast this fatalism with former President Donald Trump’s hyperactivity when supply chains were creaking early in the COVID-19 pandemic, sitting down with the people doing the actual work, asking them what’s in the way, what they need, and what’s gumming things up—and then jawboning and “executive ordering” bureaucrats to get off their rears.

Instead, the Biden administration mumbles and smirks while, in the shadows, handing over supply chains to unions and environmental activists.

Supply chains are in trouble worldwide due to Chinese disruptions, and the U.S. stands out by far, particularly the Port of Los Angeles, which—together with the adjacent Port of Long Beach—handles 40% of containers bringing both finished goods to American homes and critical parts and materials to American factories.

Without those containers, entire industries grind to a halt and shelves clear across America.

There are now 50 to 70 ships anchored off Los Angeles, with delays of up to three weeks. Los Angeles’ overflow now clogs ports across the country.

Roughly 16% of all trans-Pacific ships are currently stuck at anchor, while government-owned and unionized Port of Los Angeles strolls along at 60% to 70% of capacity, closed evenings and Sundays.

The sister Port of Long Beach did implement so-called 24/7 operations several months ago—a magic wand Biden dangled for the Port of Los Angeles on Oct. 13. But in reality, “24/7” at Long Beach means only one of six terminals, and only Monday to Thursday.

Apparently, “24/7” in government-speak isn’t what it means to the rest of us. Not surprisingly, since it’s not the union’s job to make things easy, it’s fought automation for years to protect its $200,000 salaries, while imposing arcane rules on truckers that make it a nightmare to do pickups.

The chokehold is sending factories and retailers nationwide into panic mode, not only for the risk-the-company Christmas season, but for the critical supplies and materials needed to run their own factories.

Home Depot and Target resorted to chartering their own ships, only to run into the meat grinder of inland supply chains. Analysts are predicting the chaos could last into 2023.

Because imported resins and materials are necessary in food production and delivery, even grocery store shelves are now clearing across the country. Nearly 20% of beverage and bakery products are out of stock nationwide, while Costco and Sam’s Club stores are reimposing purchase limits on some goods.

Across the states, shortages are being reported in bread, meat, juices, and now, diapers. Even dairy—critical for kids—is dwindling to core products amid driver shortages.

Parked ships are easy to see, but ports are just the beginning. Once goods get off the ship, there aren’t enough truckers, or enough chassis to carry the containers, or enough warehouse space, or enough rail capacity.

Railhead waits are now averaging 10 to 20 days while warehouses in Los Angeles are already 98.8% full. It’s now so expensive to import that containers ship back empty, leaving U.S. products to sit on trains too full to take new loads, which back up the ports and block them from unloading incoming ships. It’s layer after layer, with supply chains failing at every stage like dominos.

The go-to excuse for the administration and the media is that import volumes soared amid COVID-19, so it’s all just too much. The truth is, the Port of Los Angeles’ own numbers say containers handled are actually down 1% from a year ago, and rose just 11% in the two years through August. That’s half the jump from 2009 to 2011, when supply chains were not collapsing.

As comedian Jon Stewart remarked about the 2008 financial crisis: This isn’t a perfect storm; it’s a regular storm, and we have a s—– boat.

So, what is driving the chaos? Government, along with union chokeholds, environmental and labor mandates on truckers, mandates on supply chain workers across the board, crony trade restrictions, and excessive unemployment benefits, nationwide, but especially in California.

Remember, too, that this is all before Biden’s vaccine mandates kick in. California truckers, in particular, have been socked by the state’s notorious AB 5 law restricting gig workers and independent contractors, combined with truck emission mandates introduced just last year that can mean tens of thousands of dollars out of pocket.

Many truckers have already decamped to greener pastures in friendlier states.

Finally, crony trade restrictions like the century-old Jones Act can actually make it cheaper to import from China than to ship goods domestically, knocking internal shipping as an option.

If Biden is serious about solving supply chains, he needs to get ports, truckers, railroads, and warehouses back to work.

That means loosening union chokeholds on critical infrastructure, using the Taft-Hartley Act if needed. It means clearing out labor and environmental mandates that ban or disincentivize flexible workers and contractors. And it means draining the swamp of crony and environmental regulations that gum up supply chains with 100-year-old detritus on top of whatever activists are banning this week.