Some bits of history on these "more modern" gas cooled graphite moderate reactors....HC

For links and diagrams please see article source.....

Posted for fair use.....

steveheiser

Wed, Dec 2 2009

uranium oxycarbide

fuel

prismatic

magnox

Peach Bottom

next generation nuclear plant

INL

VHTR

Idaho National Laboratory

particle

duncan williams

uranium dioxide

NGNP

dragon

helium

AGR

UCO

triso

very high temperature reactor

Advanced Gas Reactor

pebbble

DOE

UO2

reactor

Babcock & Wilcox

Under The Hood With Duncan Williams

pellet

More

Under The Hood With Duncan Williams - VHTR - Prismatic Reactors

VHTR- Prismatic Reactors

- By Duncan Williams -

The Idaho National Laboratory (INL) recently announced the successful testing of a new type of a coated nuclear fuel for its Advanced Gas Reactor Fuel Program. At the center of this new particle is a nuclear fuel kernel made by Babcock and Wilcox known as uranium oxycarbide (UCO) - a mix of uranium dioxide (UO2) and uranium carbide (UC) particles.

After being bombarded with neutrons for three years in an experiment known as AGR-1, approximately 19 percent of the low-enriched uranium found in the UCO fuel kernel has been utilized. Previous nuclear fuels are capable of burning only about 10 percent or less of the uranium, meaning that even more energy can be harnessed from the UCO kernel than previously thought.

The coated UCO fuel particle is necessary for the Department of Energy’s Next Generation Nuclear Plant project. The purpose of this project is to develop a nuclear reactor that can operate at extremely high temperatures.

Aside from producing electricity, the heat produced from reactors operating between 1290-1740 F can be used for other industrial processes that require extremely high heat, such as petroleum refinement, as well as the production of hydrogen, plastic, iron, ethylene, styrene and fertilizer. Most conventional reactors operate at 570 F, precluding the use of its heat for these industrial applications.

The reactor being considered for the NGNP project is known as the Very High Temperature Reactor (VHTR). There are currently two types of gas-cooled high temperature reactors depending on the reactor core containing the nuclear fuel. In pebble bed reactor cores, the nuclear fuel is formed into spheres and stacked on top of one another. In a prismatic block reactor core, the nuclear fuel is placed inside a fuel rod which itself is inserted into a graphite block shaped like a hexagon.

Although both types of reactor cores can use the coated nuclear fuel particle technology, the VHTR is currently slated to have a prismatic block reactor core.

Although the results of the INL tests will surely change the status quo, one of the most widely used coated nuclear fuel particles currently used in gas-cooled reactors is known as tristructural-isotropic (TRISO) particles.

As shown in the diagram, the center of the particle is typically uranium dioxide, known as the fuel kernel, and is .5 mm in diameter. The fuel kernel is coated with a layer of porous carbon which serves to capture any fission product particles emitted from the fuel kernel.

Three additional layers of carbon are then applied to each particle: an inner layer of pyrolitic carbon; a mid-layer of silicon carbide; and an outer layer of pyrolitic carbon. These layers provide the structural support necessary to endure irradiation during the fission process.

The Department of Energy quickly realized the value of the coated particles and on March 14, 1972, was issued U.S. Patent No. 3,649,452, which describes the TRISO fuel particle and its use in nuclear reactors.

The hexagonal graphite block in a prismatic core slows down the energy level of the neutrons created by the fission process so that they can be absorbed by other fuel molecules to resulting in even more fission. An example of a hexagonal graphite block is shown in U.S. Patent No. 3,985,844, issued on October 12, 1976, and assigned to Nukem GmbH, a German corporation. The hexagonal graphite core (20) contains various sized bore holes (22 & 24). Some of the bore holes (22) are filled with fuel rods containing coated nuclear fuel particles, while other holes (24) serve as cooling channels for helium gas to flow. The gas-cooled prismatic block core has a long history of research and development both in America and abroad.

Early British Prismatic Block Reactors

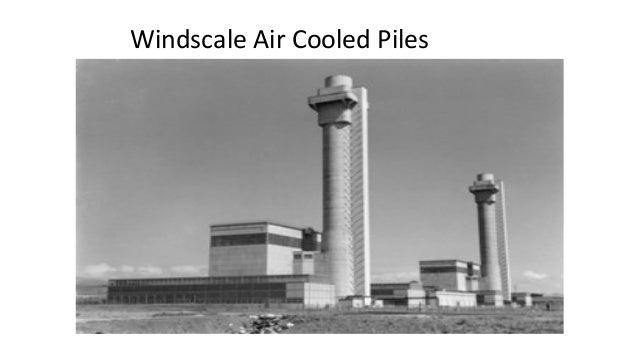

The Dragon Reactor Experiment in Winfrith Heath, United Kingdom, was a materials test facility that successfully operated between 1964 and 1975. During this time, the Dragon performed various experiments with coated nuclear fuel particles that were formed into prismatic blocks.

The 20MW helium-cooled test reactor contained 37 prismatic fuel elements, and operated with its core outlet temperature at 750 C (1382 F). The Dragon had six piping loops which circulated helium through the reactor core in order to transfer the heat created by fission away from the nuclear fuel. In the event of a total loss of electrical power, the helium piping rises as it leaves the reactor core causing the newly heated helium gas to be cooled in a heat exchanger. Slightly more dense after leaving the heat exchanger, the helium continues through piping traveling downward to the bottom of the reactor vessel to once again cool the prismatic core.

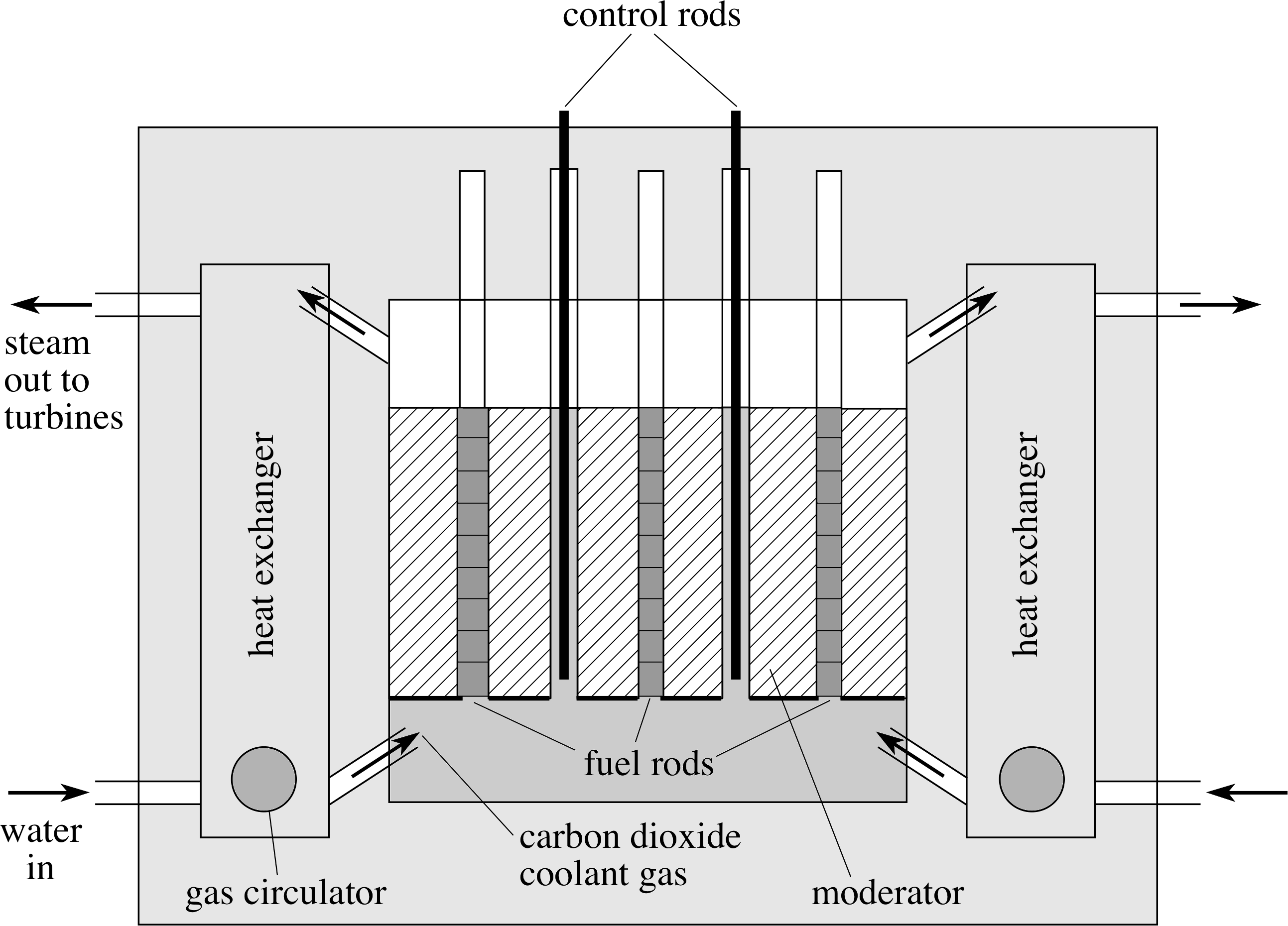

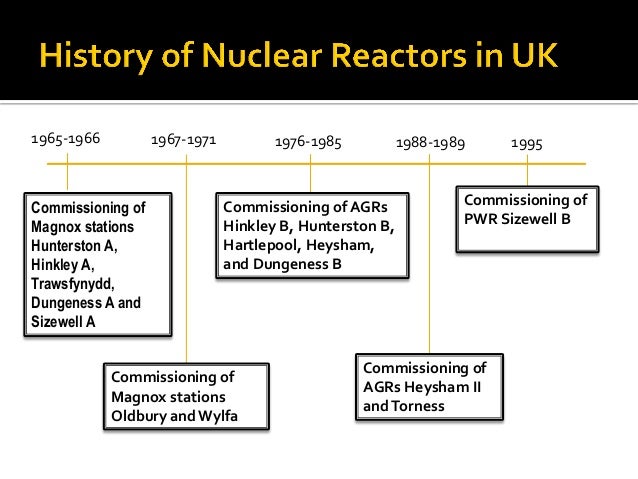

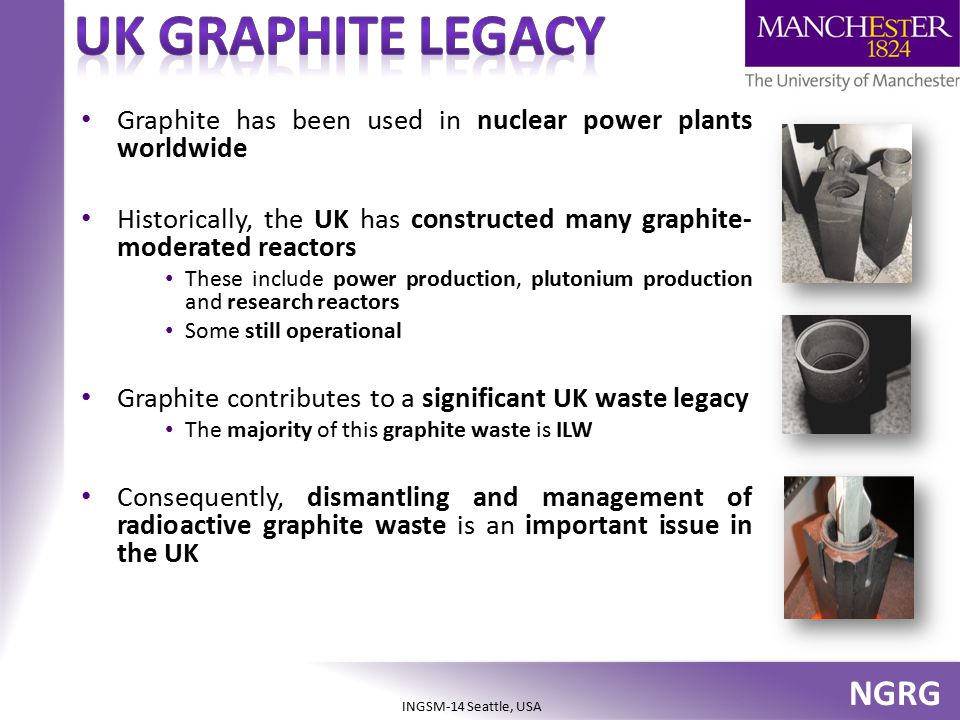

Another British design of gas-cooled high temperature reactor is knows as the Magnox reactors. Magnox stands for magnesium non-oxidizing, and describes the metal alloy of magnesium, aluminum, and other metals, used in this type of reactor. A layer of Magnox was placed on the outer surface of the unenriched uranium-238 and placed in a fuel rod as seen in the diagram. Carbon dioxide gas was used to cool the reactor, while graphite was used to slow down neutrons so that they can be absorbed by the fuel and cause fission. In the late 1950s and early 1960s, the United Kingdom produced many of these reactors and even exported them to other countries. In fact, on February 3, 1976, U.S. Patent No. 3,936,349, was issued to the United Kingdom Atomic Energy Authority, which describes the reactor core of the Magnox reactor.

As can be seen from the diagram from the patent, the fuel rods were designed with fins in order to promote the cooling of the nuclear fuel contained inside them. The Magnox material had a low melting point and limited the operational temperature of the reactor. The reactor also produces weapons grade plutonium as a result of the fission process, which raises proliferation concerns. For example, North Korea currently operates a small Magnox reactor it built and claims to have produced enough plutonium to build weapons. Because of these and other factors, Magnox reactors are considered to be obsolete and are no longer commercially available.

Early American Prismatic Block Reactors

Peach Bottom Atomic Power Station currently operates boiling water nuclear reactors at its Conwingo Pond site in York County Pennsylvania. But from 1967 to 1974, Peach Bottom was home to a 40 MW gas-cooled prismatic block reactor that performed much of the testing and data to be used to build later designs of gas-cooled reactors.

One of the fuels tested in this reactor is known as bistructural-isotropic (BISO) particles. These fuel particles were developed before the TRISO particle, and consist of only two layers surrounding the nuclear fuel kernel: a porous carbon layer surrounded by a dense silicon carbide layer. Tests showed that the TRISO particle was superior to the BISO particle, leading scientists to choose the TRISO fuel particle for use in a much larger reactor near Platteville, Colorado.

Although today Fort Saint Vrain (FSV) near Platteville, Colorado, is a natural gas powered electric plant, a gas-cooled prismatic core reactor successfully operated here between 1979 to 1989. The reactor at FSV was 330MW and utilized the uranium-thorium fuel cycle. This means that carbides of low enriched uranium, as well as thorium, were coated in accordance to the TRISO process described earlier. Each hexagonal fuel element was 14 inches across and 31 inches high. The 330 MW reactor core was so large that 1482 hexagonal graphite fuel elements were stacked together to achieve full power.

U.S. Patent No. 3,413,196, issued on November 26, 1968, and owned the Department of Energy, describes reactor core that was used at Fort Saint Vrain. As can be see in the top-view of one of the fuel elements of the FSV reactor, the graphite hexagonal structure contains fuel chamber holes (21) as well as coolant holes (23).

As can be seen in the cross-sectional view of the graphite prismatic core, the fuel chamber holes (21) are filled with either uranium or thorium coated fuel particles (25) and is sealed at the top with closure plugs (27 & 29). Helium gas flows through the coolant holes (23), removing heat produced from the nuclear fuel (25). The operation of this nuclear reactor was largely viewed as a success, however no further designs were built in the United States after this reactor shutdown in 1989.

Japanese HTTR

Japan has begun experimenting with the prismatic block gas-cooled reactor technology. In November of 1988, a 30MW reactor known as the HTTR first came on line near Oarai-machi, Japan. As can be seen in the diagram, the coated TRISO fuel particles in the HTTR are compacted into a fuel rod.

These fuel rods are then placed alongside one another inside a hexagonal graphite block which is about 14 inches wide and 23 inches high. These assemblies can be stacked on top of one another, although room is limited since the height of the reactor core is only 10 feet high. The HTTR is capable of operating at 1740 F, which is hot enough to be applied to various industrial applications.

Next Generation Nuclear Plant

In an attempt to satisfy the needs of the NGNP project, General Atomics is currently designing a reactor with a consortium of Russian coporations to build a 290 MW prismatic reactor known as the gas turbine modular helium reactor (GT-MHR).

Helium is used to cool the reactor vessel in the diagram on the right. The heated helium exits the reactor vessel and enters the power production vessel on the left. A gas-turbine generator there utilizes the heated helium and turns it into electricity. This design reduces the complexity of external components, since most of the necessary components can be located near one another.

Areva is also designing a reactor for the NGNP project. Areva’s design currently includes a 565MW prismatic block reactor core. According to Areva’s pre-conceptual design documents, the reactor core would have 102 columns of 10 prismatic graphite blocks each.

The startup control rods contain nuclear fuel that is used to generate enough neutrons to create a sustainable fission process, and are removed once the reactor achieves criticality, the point at which enough neutrons are being produced to sustain a long-term fission process. Other control rods containing neutron absorbing material, such as boron carbide or graphite, can be inserted into the reactor in order to disrupt the fission process and shutdown the reactor. The Areva documentation also suggests that it is investigating the use of uranium oxicarbide (UCO) as the nuclear material, instead of uranium dioxide (UO2) used in other designs.

The news from INL regarding the success of the coated UCO fuel particle is the most recent development relating to gas-cooled high temperature nuclear reactors. Although there are still more tests to be performed at the INL on the coated UCO fuel particle, the VHTR will almost assuredly use this new nuclear fuel. Although the nuclear technology was developed decades ago, material science is slowly catching up to this technology allowing gas-cooled high temperature reactors to reach their full potential.

Last Week's Column:

Under The Hood With Duncan Williams - The Evolution of the Pebble Bed Reactor

The Evolution of the Pebble Bed Reactor - By Duncan Williams - One of the more promising nuclear reactor technologies known today is the pebble bed nuclear reactor. Offering many advantages over conventional reactors, the pebble bed reactor gets its name from the type of the nuclear fuel it consumes. Just like conventional ...

About Duncan Williams

Duncan Williams graduated from the University of Florida in 1994 with a B.S. in Physics, and a minor in mathematics. Upon graduation, he was commissioned in the U.S. Navy where he completed training in the Navy’s Nuclear Propulsion program. He then served onboard an aircraft carrier, the USS Theodore Roosevelt, as a reactor control division officer. Onboard, he was responsible for the operation and maintenance of the electrical and mechanical components that make up the reactor control systems. This includes the control rod drive mechanisms, the reactor safety and emergency systems, the reactor coolant pump systems, and the ion exchangers. He also developed and implemented ship-wide reactor safety drills in order to educate sailors in reactor safety.

Duncan then transferred to the U.S. Naval Academy, where he served as a senior instructor teaching Thermodynamics to senior cadets. While serving as an instructor at the Naval Academy, Duncan attended night law school at the George Washington University Law School. After receiving his J.D. in 2004, he resigned his commission and began working as an intellectual property associate with Kenyon & Kenyon LLP. While at Kenyon & Kenyon, he drafted numerous patents relating to medical devices, electronic devices, telecommunications, as well as other technologies. He also has experience in all stages of patent litigation, and has represented numerous Fortune 500 companies in protecting their intellectual property rights. Duncan is currently an intellectual property associate at Blank Rome LLP.

If you have questions, comments, or know of a patent that you think Duncan should review E-mail Duncan Williams>>

duncan@nuclearstreet.com